The ready-to-use and fully programmable GCube Preforma automation system has been developed by Gefran in order to meet the requirements of various automation architectures, and particularly the needs of companies manufacturing plastic processing and heat treatment machinery. Designed to combine the potentialities of a single-board platform and the flexibility of a modular structure, it offers high versatility and scalability, depending on the type and complexity of the machine.

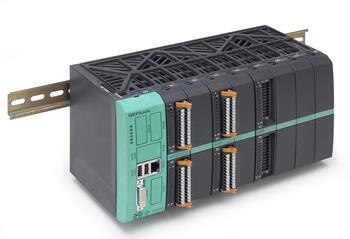

ePCLogic400, the heart of the system, manages all functions such as sequence control (PLC), process management (Function Block), data programming and display (HMI), and connectivity (Ethernet, CAN, serial ports, USB). Characterised by a modular design, consisting of a main rack which houses the CPU and the I/O boards, ePCLogic400 is supplied in a ready-to-use “package configuration”. The system can also be extended by integrating new modules and, in the distributed configuration, by implementing fieldbuses.

The system is installed on DIN rails, while data are saved on solid-state drives and/or on convenient removable media such as SD cards, able to store process information collected over several years, ensuring their complete integrity. Dissipation occurs passively, without fans, and this contributes to the reliability of the whole system and makes maintenance unnecessary. The integrated Ethernet connection and the related services (WEBserver, VNC, Java Pages, FTP, Modbus TCP) make it possible to perform system diagnostics, meeting diverse needs in terms of safety, user levels and graphics. Data can be displayed and set through the ePanel and eGT-I user interfaces, available with screens of different sizes, in horizontal or vertical version as well as with a keyboard or touchscreen.

A single standard, integrated, easy-to-use programming environment allows rapid development of the application software. Communication is supported by a wide range of ports - including Ethernet, serial, CAN and USB ports - and several protocols, such as GDNet (Ethernet-based real-time protocol), Modbus TCP, Modbus RTU and CANopen. The flexible architecture and the easy integration typical of the Gefran devices (power controller, driving systems, sensors, instruments) comprise the main features of this solution. Finally, the offer is rounded off by software applications that have been tried and tested on machines: open and fully customisable, they reduce or even eliminate engineering costs.