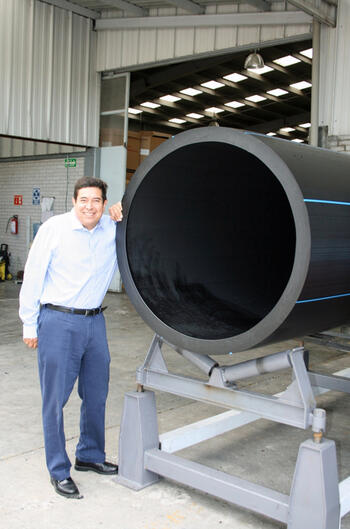

Mexican manufacturer of polyethylene pipes, Valtic, selected the technological solutions of Tecnomatic to strengthen its market leadership position. “In less than ten years the company passed from an output of 1,500 kg per year to over ten thousand tons placing itself as a processor recognized for the quality of its products. This is a great achievement in a relatively short time, and merit for this can be attributed to our capacity to invest in innovation, quality, efficient people and machines. Doubtlessly Tecnomatic has been and is continuing to be the best choice for our projects and applications,” says José Espinosa Bravo, owner and chairman of the Mexican company Valtic.

With over 20 years of experience in the manufacturing of plastic pipes, José Espinosa Bravo appreciates the technology side of a supplier but also the level of its services and its ability to cooperate. This way of thinking has taken the company to change completely its production equipment, investing in the very latest technologies. This change will see completion with the arrival of two brand new gearless extruders of the Zeus and Zephyr series.

Today Valtic is the leading manufacturer of polyethylene pipes in Mexico running 8 lines all supplied by Tecnomatic which produce pipes ranging from ½” to 48” (1,220 mm) in diameter; the first and only manufacturer of pipes in this size in Mexico and Central America. Thanks to the adoption of high productivity lines, like the recent one for pipes from 4” to 10” and 800 kg/h output, the company has been able to place itself as one of the most advanced processors thanks to its ability to deliver high quality pipes in high volumes and in short times.

“The choice of gearless extruders is a further sign of the attention and care the company is dedicating to its products in terms of quality and technology. We are proud to be the first company in the American market to introduce state-of-the-art solutions and technologies for pipe manufacturing,” adds Juan Manuel Rebollo, plant manager at Valtic.

Valtic is already running several Tecnomatic extruders of the Vega series in the L/D 37 size and the whole range of helical die-heads of the Venus series, featuring the “Pipe Air Cooling” system. In addition, Valtic has recently purchased two gearless extruders with L/D 37 and 40 sizes. The Zeus series represents a tried and tested solution developed by Tecnomatic in the market of the gearless extruders. Introduced four years ago it has met with success not only in Europe but also in the Middle and Far East. The machine offers several solutions in terms of energy saving and performance. Thanks to important developments in the technology of torque motors aimed to increase their reliability and efficiency, this extruder ensures outstanding savings in the production of plastic pipes.

Offered in the 40 L/D size as the evolution of the Zeus series, the Zephyr range sets new standards in the gearless extruder technology. The Zephyr extruders represent the best gearless concept available from Tecnomatic, and are further expanding Valtic’s experience with this engineering solution. The principle of the Zephyr machine is offering a higher specific output with improved optimization of the plasticizing step, even at comparatively low melt temperature and low energy consumption (e.g. inferior to 200 Wh/kg for the Zephyr 60.40 model at 800 kg/h). Further features common to all the gearless extruder series are low noise operation and low motor rpm rates, virtually eliminating maintenance operations. In the standard configuration, the machines have spiral grooved bush, bimetallic barrel with Colmonoy-reinforced screw, water-cooled inverter and modules for monitoring power consumption.

Zephyr extruders are offered in four screws diameters with maximum output of 1,700 kg/h. The 75 and 90 models can be also equipped with a traditional gearbox (one or two steps) and water cooled motor and inverter. On request, a gearbox version is available for the 45 and 60 models too.