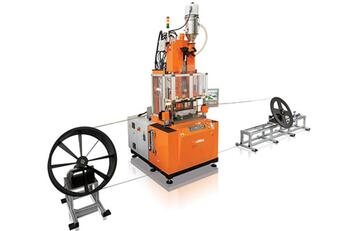

The NT Series Wires machines developed by Turra, a division of the IMS Deltamatic group, are offered as an ideal solution for the production of cables, wires and components, such as diamond wire, in which the cable is positioned transversely and adjacent to the tiebars. The 60- and 80-ton presses, the cable-tensioning system, the mould, the mould heater and the peripheral equipment all stem from the technology and experience acquired by Turra, which have made this company one of the world’s leading suppliers of solutions for special technical applications like the overmoulding of diamond wire.

One of the most recent versions developed for this purpose, recently unveiled at an open-house event at the company’s headquarters in Calcinate (near Bergamo), is the 60-ton mod. NT-60-2C, which has no table and features two tiebars. “Diamond wire is used for cutting granite and marble and it is assembled, as a tool, on so-called multi-diamond wire machines. This is a niche market in which Turra is among the world leaders”, remarks Daniele Vaglietti, business strategy director of the IMS group.

The Turra product range includes three families of machines: without table, with a linear table and with a rotary table, all available in a wide range of clamping forces (from 60 to 120 tons). All the machines are equipped with an inverter-driven pump which, together with the insulating mats mounted on the plasticising cylinder, allows energy savings of around 40% compared with previous versions. The touchscreen-type operator’s panel makes it possible to modify ergonomically the machine parameters, to manage alarms, and view statistics regarding productivity. The machines can also be equipped with a dedicated system for remote service support, which allows rapid access by IMS engineers. All the machines can be integrated with automation devices and Cartesian, Scara or anthropomorphic robots. Special applications are available on request.