For the first time in its history, Toshiba Machine, whose distributor in Italy is EPF Automation, came to a European fair with a system for the moulding, inspection and unloading of plastic components. This occasion represented the coming together of, on the one hand, the Japanese company’s need to offer its solutions for fully electric injection moulding on the Italian and European markets, and, on the other, the desire of the distributor, based in Carrù (in the province of Cuneo), to present the know-how that it implements in proposing robotised automation of production processes. These are, indeed, the ingredients that first led these two companies to become partners in order to supply, in Italy and Europe, a wide range of high-performing and reliable machines designed to meet the full range of injection moulding needs.

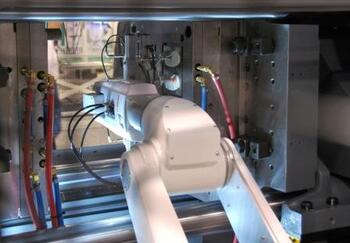

At Plast 2015, two years after the start of this collaboration, they presented an EC130SX electric press with two integrated TM robots, thereby providing a concrete demonstration of the entire production cycle. The machine moulded a polyethylene component in a 22-second cycle; the pieces were handled by an anthropomorphic robot (model TV1000) and quality control tested with a 3D vision system, before being transferred to a conveyor belt and then unloaded by a Scara TH650A.

The expertise of EPF Automation, developed in over fifty years on the market, together with the experience of Toshiba Machine in the plastics sector, are allowing the design and marketing, in Italy, of integrated solutions with anthropomorphic and Cartesian robots, 3D vision systems and automations, with view to achieving better optimization of production processes. In addition to global partnerships, the Piedmont-based company is also involved in collaborations developed within its own area. In an example of the kind of local synergy that represents an important strategic factor for EPF Automation, the mould used at Plast 2015 was supplied by Europlast, which is based in Cherasco (Cuneo).