The leitmotif of Gefran attendance at K 2022 will be the in-depth know-how in the production process that distinguishes and positions the company among the major partners for OEMs, system integrators and end users - thanks to a line-up that includes innovative products - and the Gefran Soluzioni business unit active in the design and manufacturing of automation systems, electrical panels and software for the plastics industry.

"Gefran will take part in K 2022 with great enthusiasm, thanks to all that the group has been able to achieve against the backdrop of an extremely complex market scenario. The fair will provide an opportunity to confirm - to our customers and partners - our steadfast commitment as a leader of technological evolution thanks to our deep knowledge of the main applications in the field of plastics gained in over 50 years in the sector. Excellent products, on-going innovation and the use of open communication standards are the basis of our line-up and the key for seizing the many opportunities offered by the digital transformation," said Marcello Perini, CEO of Gefran.

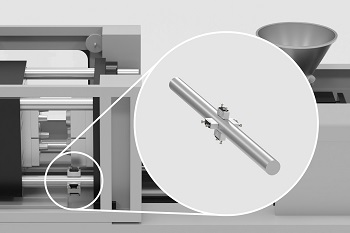

Twiist, the innovative multi-variable contactless position transducer, revolutionizes measurement technology in automation systems, even redefining the role of sensors. In addition to the position, in fact, the versions of Twiist equipped with CANopen and IO-Link digital outputs record other process variables, including speed, acceleration, tilt angle, actual and peak temperature reached, hours of work and number of km travelled by the slider. The first of its kind with a patented three-dimensional Hall Effect measurement system, the Twiist transducer is used in various plastics processing applications.

Twiist, the innovative multi-variable contactless position transducer, revolutionizes measurement technology in automation systems, even redefining the role of sensors. In addition to the position, in fact, the versions of Twiist equipped with CANopen and IO-Link digital outputs record other process variables, including speed, acceleration, tilt angle, actual and peak temperature reached, hours of work and number of km travelled by the slider. The first of its kind with a patented three-dimensional Hall Effect measurement system, the Twiist transducer is used in various plastics processing applications.

The GRx family of single-phase solid-state relays will also be in the limelight at the fair. This scalable Gefran platform with incremental performance and integrated diagnostics, for the control of electrical resistances in industrial heating systems, is available in the GRS-H, GRP-H and the latest GRM-H versions. The latter, in particular, combines the typical characteristics of a power controller with the compact size of an SSR. This relay allows the user to manage linear and non-linear resistive loads such as MoSi2, Sic, SWIR, graphite and transformers. In addition, the GRZ-H relay will also be unveiled - a further evolution of the two/three-phase model – to be launched on the market in the coming months.

The new KS-I industrial pressure probe, equipped with IO-Link 1.1 interface and advanced diagnostic features, measures pressure and temperature at a sampling rate of 1,000 samples/sec. The KS-I probes are able to communicate with the IO-Link Master at COM3 speed, equal to 230.4 Kbaud, the highest currently reachable.

The new KS-I industrial pressure probe, equipped with IO-Link 1.1 interface and advanced diagnostic features, measures pressure and temperature at a sampling rate of 1,000 samples/sec. The KS-I probes are able to communicate with the IO-Link Master at COM3 speed, equal to 230.4 Kbaud, the highest currently reachable.

The Hyperwave range, synonymous with high-performance magnetostrictive technology, will include innovative products too. Today, in addition to the models with synchronous analogue and serial output, this family of contactless position transducers includes WPL sensors, with IO Link V 1.1 digital interface, to meet the Industry 4.0 and WPA-F and WRA-F requirements, the first on the market integrating the Hyperwave technology and Profinet connectivity. The WRA-E model with EtherCAT communication further enlarges the company’s line-up. On display at the fair there will also be the new Gilogik III series of I/O systems, an evolution of the Gilogik II for the management of digital inputs/outputs on EtherCAT fieldbuses.

Finally at K, Gefran will be exhibiting the QE2008-W system, an evolution of the complete range of QE1008-W wireless sensors for an even more accurate measurement of tiebar deformation and mould clamping force in injection moulding and die casting applications. The QE2008-W sensor now incorporates new features including: Bluetooth 5.0 connectivity, long-lasting lithium polymer batteries and fast recharge, cavity pressure monitoring. It shares with the previous model simple and quick assembly, thanks to the patented press-on magnetic technology, which allows the strain gauge to adhere directly on the measuring surface, without the need for glue and heat treatment.

Much emphasis will also be devoted to Gefran Soluzioni, the business unit of the Gefran group that works closely with machinery manufacturers and system integrators on the creation of complete programmable automation systems. On the basis of a wide range of templates, the Gefran Soluzioni team of engineers is at the service of customers for the development of optimized application software in terms of process control and display, for the specific needs of plastics processing machines: from injection to extrusion and blow moulding, to mention but the most important.

Much emphasis will also be devoted to Gefran Soluzioni, the business unit of the Gefran group that works closely with machinery manufacturers and system integrators on the creation of complete programmable automation systems. On the basis of a wide range of templates, the Gefran Soluzioni team of engineers is at the service of customers for the development of optimized application software in terms of process control and display, for the specific needs of plastics processing machines: from injection to extrusion and blow moulding, to mention but the most important.

A fundamental aspect of Gefran's line-up lies in the ability of individual products to generate useful data both for process control and for condition monitoring and maintenance, as they are designed to be integrated into machines that use the most popular fieldbuses, such as IO-Link for the pervasive digitalization of production plants, EtherCAT, a widespread high-performance architecture, OPC-UA and MQTT for the rubber and plastics industry.