Maag Group is a broadly diversified global solutions provider of pump and filtration systems, pelletizing and pulverizing systems, recycling systems and digital solutions. More and more new developments in plastics are being made in China, one of the strongest growth markets in the world. Maag Group takes this into account and will be present at Chinaplas in Shenzhen from 17 to 20 April. Company experts on site will inform visitors about its product portfolio for the polymer industry.

The Maag Group extrex gear pumps GA are designed for common thermoplastic extrusion applications and offer a high overall efficiency and hence minimum abrasion due to leading gear and bearing technology. They convince with low pulsation pump action also in cases of high differential pressure and a simple and compact design. The newly developed extrex recycling pump ensures reliable extrusion in the recycling process. The extrex features an optimized geometry that, in many cases, eliminates the need for an upstream protective filter, saving space and reducing the energy required for heating and drive power.

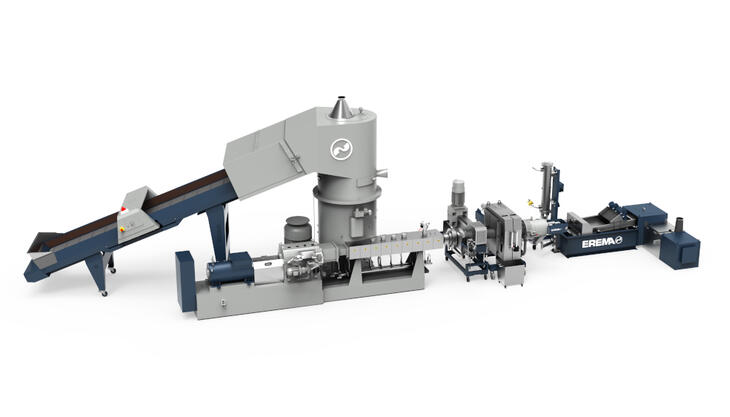

Maag Ettlinger ERF 350 is a high-performance melt filter for filtrating heavily contaminated polymer feedstock. The filter is self-cleaning with a rotating, perforated drum, through which there is a continuous flow of melt from the outside to the inside. A scraper removes the contaminants that are held back on the surface and feeds them to the discharge system. This enables the filter to be used fully automatically and without any disruptions over long periods without having to replace the screen. The advantages: reliable melt filtration, ultra-low melt losses and good mixing and homogenizing of the melts.

The Baoli-3 strand pelletizer is outfitted with German-made core components and has been designed for use with both hard and soft pelletizing materials. The most noteworthy highlights are its compact design that features height-adjustment, left-side/right-side control capabilities that provide greater operational flexibility, and reduced noise generation during operation. At the same time, it offers easy access for cleaning making it easy for maintenance, material changes, and color changes. The Baoli- 3 also provides high reliability, improved handling, and an optimized cost/benefit ratio.

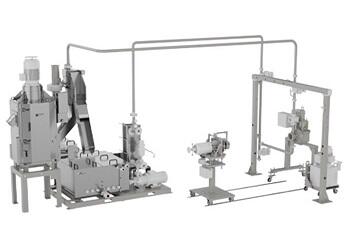

The Zhuli system is a highly flexible, cost-efficient underwater pelletizing system designed for use with standard products, such as filled polyolefins, polyesters, and thermoplastic elastomers. Zhuli’s cutting tools deliver spherical pellets of the highest quality that are ideally suited for further processing, with throughput rates of up to 1,200 kg/h. The pelletizing system has a small footprint and is simple to operate.