At the coming K 2013 fair, Torninova will be exhibiting at its stand (A19, hall 17) a Compact Stretch 1.000 line for the production of stretch cast film along with the new RV 40 co-rotating twin screw extruder for colour masterbatches. The former equipment enables the production of film of 1 metre in width made up of 3, 5 or 7 layers; it is a compact flat-die system taking up less than 75 sq.m whose components have been specially developed for guaranteeing top quality products, while ensuring at the same time maximum flexibility, reliability and energy efficiency. The line can produce film rolls in the manual and machine processable versions, as well as in the Jumbo version at an output rate of 850 kg/h. The line's equipment includes: self-regulating flat die, double chill-roll system with axial torque motors, integrated thickness sensor, and ultra-compact gearbox for the extruders.

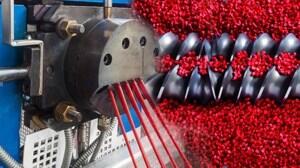

The co-rotating twin screw extruder for colour masterbatches incorporate components subjected to special treatments to increase their energy and process efficiency as well as operating life. The screws are available in lengths up to 42 D and diameters from 30 to 92 mm, have a modular design for adapting to various production needs and process types, and include self-cleaning elements mounted on grooved shafts. The screw's geometry has been designed to mix and homogenise the viscosity of compounds and masterbatches in order to reduce mechanical and thermal stress that may deteriorate the end product, however ensuring greatest dispersion and distribution uniformity of additives and colours into the polymer matrix. The rectangular section of the barrel contributes to maintaining the temperature distribution constant and uniform inside the plasticising chamber. The cooling system too has been designed for ensuring optimum temperature control for both screws, as well as high energy efficiency: two crucial factors above all when processing heat-sensitive products.