The new Cap Box integrated system with flexible layout has been developed by Green Box (attending K 2013 in booth H03, hall 10) to monitor the quality of caps and closures. The system concept is based on the consideration of how, in the caps and closures production process, cycle times and wall thickness have been increasingly reduced, as a result requiring highly efficient cooling and quality control solutions. To this purpose, the system can be supplied as an integrated solution or as a stand-alone unit for special operations.

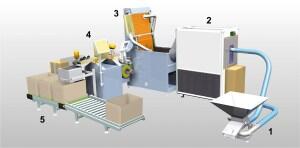

Basically, Cap Box is a comprehensive line of machines designed and manufactured to be able to cope with increasingly higher output rates while ensuring optimum quality for the caps and closures produced. The line consists of five sections for five process functions: 1) conveying and feeding; 2) cooling and stabilisation; 3) positioning within the quality control system; 4) selecting and rejecting items not complying with the technical specifications; 5) packaging.