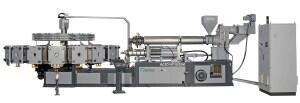

For the production of solid bases for linear brooms (both household and industrial ones), Presma supplies rotary injection moulding machines with between 10 and 18 stations; these solutions guarantee high output rates thanks to the elimination of downtimes for cooling of the component in the mould, as well as high quality processing. Actually, 10-station machines have been used for many years, but growing demands, in terms of both quality and quantity, have prompted the development of versions with 12, 15 and 18 stations, featuring larger, electrically-driven injection units and digital controls, to ensure optimal management of the moulding parameters. Platens and clamping forces have been increased to accommodate moulds that can have as many as 8 or 14 cavities, depending on whether they are to be used for the production of industrial or household broom bases.

The machines come with a single nozzle, which makes it possible to use both the moulds normally destined for traditional machines and those that are used on rotatory machines for two-component moulding. They can be equipped with a dual-nozzle head and double injector cylinder with two punches, each of which feeds one nozzle. This allows filling of the mould in two separate points, thereby avoiding, in the presence of 8 cavities or more, excessively long sprue channels and reducing cavity balancing problems by half.

The 10- and 12-station versions feature a hydraulically-operated 80-mm plasticizing unit; an electrically-driven version with an inverter (Elettra) can also be supplied, on request. As regards the 15- and 18-station solutions, on the other hand, only the Elettra version features a 100-mm plasticizing unit; this allows greater plasticising capacity, better exploitation of the additional cooling stations, and energy savings of 20-30% compared with the hydraulic version. The standard versions can inject up to around 2,500 g of material (PP). Still using polypropylene pellets (even recycled), which guarantee efficient feeding, it is possible, using the new models and 8-cavity moulds, to produce bases weighing 150 g (1,200 g of material) at a rate of over 1,200 pieces per hour, which corresponds to a cycle time of under 20 seconds.