In 2013 Gamma Meccanica introduced the GM50 Compac in a new version. Its aim now is to redesign the whole range of machines by the end of 2015. The new design mainly concerns the feeding unit and the extruder, while the most significant changes have involved mainly the Compac lines (feeding system featuring silos with shredder/pre-compactor), where these components are assembled together to ensure greater stability, as well as to produce installations that appear more integrated and compact. Particular features of the new generation of lines are the improved insulation, for greater energy efficiency, the optimisation of the extruder feeding zone, the particular attention to cooling, and the newly designed bush-cylinder assembly. In addition, screws with a new profile have been used, which make it possible to increase the output of these machines. The electrical panel is installed on the same base as the extruder; this solution, by avoiding the need to disconnect the cables for transport and then reconnect them in the assembly stage, eliminates the risk of errors when installing the machine at the processor’s facilities. It also means shorter installation times and easier and faster shipping.

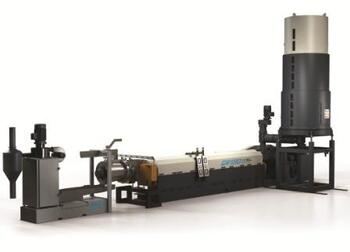

At Plast 2015 Gamma Meccanica exhibited its new-generation GM65 Compac line, a particular feature of which is the possibility of loading it directly onto containers without having to disassemble the feeding unit and extruder. A TDA 3.4 liquid ring cutting system is installed on the line, which is designed to recycle film, fibres, fabrics and yarns.

Also on exhibition at the fair were the G-Moby lines, which are getting very positive feedback from the market. These lines allow PET to be reclaimed, re-graded and “super cleaned”, obtaining rPET granules that can be used in the production of food packaging in compliance with FDA and EFSA regulations. In this regard, Gamma Meccanica was recently notified, by the FDA, that, following review and approval by the Fraunhofer Institut für Verfahrenstechnik und Verpackung, which conducted tests on materials recycled with the G-Moby line, it has been awarded the NOL (No Objection Letter). The line also allows re-grading of PET for applications requiring high viscosity.