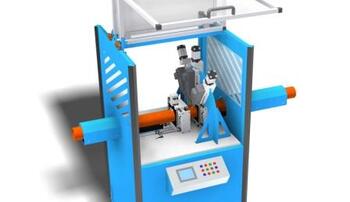

The latest technology presented by Baruffaldi Plastic Technology to the plastic market is the off-line drilling machine for drainage pipes, with three drilling heads to carry out three holes at angles around the circumference of the pipes.

The machine has an overall solid structure, especially in the support plate to which the drilling units are fastened, adjustable in their position relative to the pipe, to be very flexible in production. This is one of the strongest point of this kind of units: their adjustment capability, for example for other distances between centres to be drilled in the future, that the operators can obtain just by adjusting the setting.

The clamping mechanism moving the pipe forward by the distance between centres maintains the grip on the pipe during the drilling operation and allows a high precision performance.

Thanks to the pipe detecting sensors, the drilling machine doesn’t stop: it continues working hard for a daily guaranteed production!

In this configuration the plant can come complete with the suction device for dust and swarf, or to be connected to the customer dust extractor; either include the feeding and feed out tables as pipe support and store units, or be used like a semi-automatic machine with a manual feeding.

Baruffaldi Primac drilling units are not only available as off-line machines but also as in-line units, synchronised with the extrusion speed. They are suitable for drilling both pipes and tubular profiles. The company uses top quality components of leading brands and offers to the customers its technical assistance for the project and manufacturing of the right plant to have a quick return on the investment.