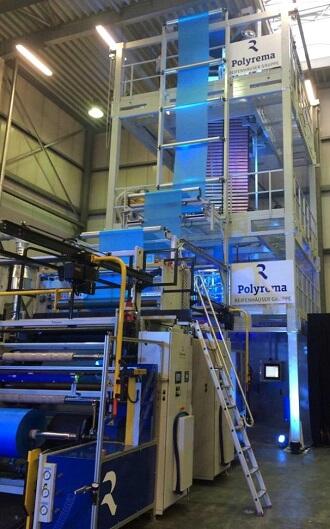

A plastics processor has recently ordered a line featuring exactly the details which Polyrema wants to present in the run-up to the plastics trade fair K 2016 in Düsseldorf. The single-layer ("mono") blown film line was extensively tested under production conditions: HDPE film and a biodegradable film (from Basf resin) were produced.

The critiziced ubiquitous HDPE films used as ultra-thin T-shirt carrier bags for fresh produce are one of the reasons for the growing trend towards the new ecological films which are demanded above all in France today. Manfred Kurscheid, managing director, says: "Shopping bags made from this kind of film can be reused as bio-waste bags or they can be composted. The new line can produce both types of films: classical and biodegradable ones!”

Polyrema demonstrates that the capabilities of mono-layer lines are far beyond this application: with an additionally installed Ultra Flat Plus unit it is possible to produce a high-quality film of slightly increased strength which can be laminated and coated. Marcel Perrevort, sales director at Polyrema, states "This film can also be laminated with paper to produce, for example, the typical wrap film for butter packaging".

A further highlight proposed by Polyrema for the production of biofilm is a special screw cooling system installed in the Reifenhäuser extruder. "The optimal processing temperature of the raw material is relatively low. Thanks to the cooled screw we have very good processing conditions with this material“, explains Marcel Perrevort. Although it produces "only" monolayer film, it is equipped with a two-layer blown film die head. "The melt is divided in the blown film die in a ratio 50 to 50 and then combined again into two layers. As a result, the film structure is improved in terms of stability and strength, despite of using only one raw material", comments Manfred Kurscheid.

It was just these quality features that made the processor opt for the Polyrema line. In the future, he will produce on it mainly draw tapes for garbage bags. The processor puts high value on a superior-quality film with low stretching behavior to prevent that heavy garbage bags are becoming longer and longer on the path to the dustbin. "A line equipped with a two-layer blown film die and Ultra Flat Plus is ideal for such applications", was Manfred Kurscheid's first resume.

Polyrema is a member of the international, family-operated Reifenhäuser Group with headquarters in Troisdorf and 9 subsidiaries active in plastics machinery engineering, upstream and downstream technologies, and applications.