The requirements in the field of electronics and telecommunications are ever more stringent with the progress of technological development that characterizes this industry. From the miniaturization of circuits at high operating temperatures and the integration of functions to the obvious cost containment requirements to keep pace with the mass diffusion of the most advanced engineering: the challenge for designers is always open. Also in the field of materials, acceptable compromises are becoming less and less, and especially polymers are often required to perform at the limit of application possibilities.

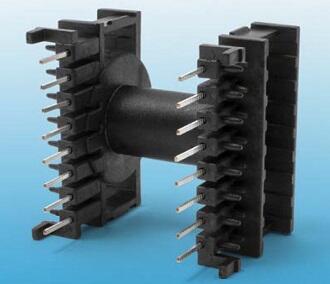

Although all electrical machines and electronic systems are object of miniaturization processes, for inductors and transformers this trend has to come to terms with the ever-increasing performance requirements inevitably involving high operating temperatures. These are the reasons why the Italian company F.lli Motta decided to manufacture the spool of a series of transformers on ferrite using the Larton G/40, a Lati material based on PPS thermoplastic resin with 40% glass fiber reinforcement.

All the components that make up a transformer are subject to a host of equally imperative project requirements. First, the temperature resistance is set, in this case, at a minimum of 150°C in continuous. Second, self-extinguishing properties for this project are engineered to meet UL94-V0 at 0.42 mm. Dimensional stability of the product and the molten compound’s ability to fill even very thin cavities (less than half a millimeter) during the molding process are also fundamental. Finally, the possibility to insert current-carrying pins without incurring problems of breakage or deformation.

Larton G/40 is the perfect response to these demands due to the intrinsic self-extinguishing properties of polymer, the excellent thermal performance and resistance to aging that stands comparison even with synthetic materials of the upper price range.