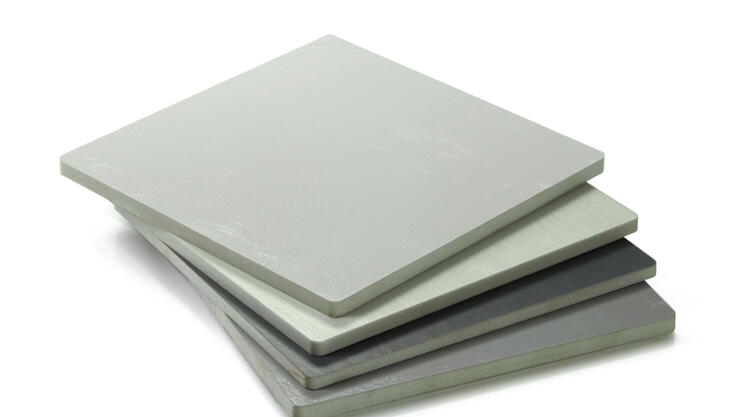

The 3D printing and additive manufacturing solutions company, Stratasys announced the new advanced material FDM Nylon 12CF, a carbon fibre-filled thermoplastic strong enough to replace metal components in a range of applications. The first high-performance composite material to replace a range of metal applications available for Stratasys FDM technology, FDM Nylon 12CF is ideal for rapid prototyping, strong, light-weight tooling and end-use parts.

Containing 35% chopped carbon-fibre by weight, FDM Nylon 12CF offers the best stiffness-to-weight ratio among Stratasys FDM thermoplastics, meeting functional performance testing demands in automotive, aerospace, recreational goods, and industrial manufacturing sectors. FDM Nylon 12CF will be of special interest for the following users and use cases:

- design engineers that need to rapidly produce strong, light-weight and rigid components for functional prototyping, thus reducing new product time-to-market;

- manufacturing engineers that produce manufacturing aids, such as jigs and fixtures, where high material stiffness and strength is required and there is great benefit to the significant weight savings over metal tooling components

- design engineers making low-volume production parts with unique structural requirements, where high strength in one-direction is required.

FDM Nylon 12CF beta customer Utah Trikes is taking advantage of the material’s properties throughout its development and production process to make significant cuts to its product development times. “The excellent strength and stiffness-to-weight ratio of the FDM Nylon 12CF material is a game changer for us. It means we can prototype almost every part of our product on Stratasys FDM 3D printers in under two weeks, where in the past it could take us over two months”, said Ashley Guy, president and CEO of Utah Trikes.

“I no longer have to constrain my designs because of prototyping limitations. Now I can focus on designing better, more functional parts without worrying about how to shape the aluminium or how to lay up carbon fibre onto the moulds. Stratasys FDM Nylon 12CF parts can be 3D printed faster, with superior stiffness-to-weight performance and with better repeatability than any other 3D printing technology or vendor we’ve seen”, continued Guy.

“We believe

that the impressive strength-to-weight ratio of the FDM Nylon 12CF is

transformative for many industries from consumer goods and recreational goods

to automotive and aerospace. It enables designers to develop more practical and

functional designs and get them to market faster, without worrying about how to

prototype those parts using metal or moulding”, said Zehavit Reisin, vice

president, head of rapid prototyping for Stratasys.

“We believe

that the impressive strength-to-weight ratio of the FDM Nylon 12CF is

transformative for many industries from consumer goods and recreational goods

to automotive and aerospace. It enables designers to develop more practical and

functional designs and get them to market faster, without worrying about how to

prototype those parts using metal or moulding”, said Zehavit Reisin, vice

president, head of rapid prototyping for Stratasys.

“The very high stiffness-to-weight ratio of the FDM Nylon 12CF material makes it extremely well suited for a wide range of final part and manufacturing tooling applications where the combination of stiffness, strength and low weight is critical to the performance. Examples include drill guides, end of arm tooling, brackets, jigs, fixtures, and even metal forming tools”, according to Tim Schniepp, head of tooling solutions for Stratasys.

Expected to begin shipping in the second quarter 2017, FDM Nylon 12CF is available for the Stratasys Fortus 450mc Production 3D Printer and is compatible with soluble support SR-110. It requires an updated version of Insight software and a hardware upgrade. The material can produce parts in a layer thickness of 0.010 in (0.254 mm).