More and more often water, gas and cables are distributed, transported, channelled and protected in our cities and homes by plastic piping; as indeed are fluids, vapours and wires in our cars and domestic appliances; plastic pipes are also frequently used in the medical sector. In these and numerous other applications corrugated piping assumes a role of primary importance; thanks to its ringed structure, it is highly flexible, light and extremely resistant in relation to its weight. In addition, its resistance can increase by adding an inner layer to the outer layer, thus obtaining a double walled pipe, a structure that improves and increases the characteristics mentioned.

Specialist in the construction of corrugators and ancillary equipment, Itib Machinery International offers a range of products that includes systems both to manufacture single-wall pipes in PE, PP, PVC, PA, EVA and other thermoplastic polymers and double-wall pipes in PE, PVC and PP, with internal diameters from 4.5 up to 600 mm (with external diameters up to 700 mm).

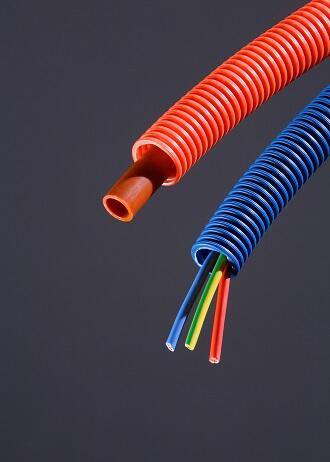

The extrusion lines for “standard” corrugated pipes are joined by those for applications that allow the reduction of labour costs and/or provide the market with products that are easy to install and use or have special physical-mechanical characteristics. Examples are lines for pre-wired corrugated pipes that have electric wires already inserted inside for the building sector, as well as lines for coating XPE or multilayer XPE-Al-XPE pipes for the plumbing and heating sector. In these applications, cables and XPE pipes, wound into coils, are unwound, passed through a square head and then inserted into the corrugated pipes using a vacuum moulding system, leaving the internal section of the pipe free for the passage of cables and smooth pipes. For the building sector, there are also lines for manufacturing corrugated pipes that have an internal layer with a reduced frictional coefficient. In this case, a co-extrusion head adds a very thin but uniform layer of silicone to the inside of the PVC or PP corrugated pipe, reducing the effort required to insert the cables.

The use of co-extrusion heads to corrugators with special characteristics allows the production of multilayer pipes for the automotive sector. These pipes must combine characteristics of mechanical resistance with resistance to chemical aggression from fluids or vapours; polyamides, fluorinated materials, thermoplastic rubbers and adhesives are used. Corrugated moulds, alternated with smooth or shaped moulds and the vacuum moulding system allow the production of pipes that alternate flexible lengths with rigid parts and that can keep a solid 3D shape once preformed with a subsequent process; additionally, the speed of the corrugator can change at suitable intervals to obtain different wall thickness. In this application and for domestic appliances as well, upon request, the corrugator comes with a device that checks for small holes in the pipe, thus avoiding additional controls.

Whilst corrugator models from F15 to F65 are suitable for small diameters in a wide range of applications, models F250, F315, F400 and F700 are suitable for underground cable ducts and rainwater or sewerage drainage pipes, which require the use of double-wall pipes with larger diameters. In these applications, solutions like aluminium moulds, to allow a more efficient heat exchange, vacuum moulding and direct cooling of the moulds, with water running directly through them, are used. The F700 corrugator, in particular, adds a “shuttle" system to the aforementioned characteristics. The moulds return to the extrusion head at a higher speed than the production one, thus allowing for a lower number of moulds than in a traditional moulds chain system, in a machine that is extremely compact, despite the sizes of the pipes manufactured.