At Fakuma 2018, HRSflow will be demonstrating the universal application of its Flexflow technology of servo-electric driven valve gate solutions based on examples of complex, high-quality parts. Produced with the help of advanced hot runner solutions, they will range from technical parts for the automotive industry to an extremely thin-walled laptop housing and an ultra-light tool box. In all cases, the ability to individually control the pressures and flow velocities at each gate makes the Flexflow technology an optimal solution for large and small applications, even with thermoplastics that are very difficult to process. As a first step in the direction of IMM integration (according to Industry 4.0 requirements), the company will present the option of using the touchscreen of the respective injection moulding machine to control the Flexflow settings, which only recently became available.

In cooperation with tool specialist GK Concept and injection moulding machine manufacturer Yizumi, HRSflow has developed and optimized a hot runner system for the production of an engine cover, using the Flexflow One technology. This servo-electric valve gate solution, which is programmed using an external Smart Interface and therefore requires no additional control unit, combines maximum precision with a broad process window and attractive cost efficiency. In the production of the large-sized component, an aluminium foil only 0.2 mm thick is first inserted into the mould and punched into shape during the closing process. Subsequently, the foil is thermoformed during over-moulding with a glass fibre-reinforced polyamide using a Flexflow hot runner system and physical foaming technology. During this back injection phase, in-mould graining (IMG) takes place, in which the fine texture of the mould is transferred both to the foil and to the polymer surface. The resulting part combines light weight with very high dimensional stability, low warpage and a premium surface without visible weld lines.

A Flexflow five-nozzle hot runner system is used for the production of the automotive spoiler also shown on the exhibition stand. A polypropylene from A. Schulman, filled with 3M’s hollow micro glass spheres, enables weight savings of up to 15% compared to the unfilled version. Thanks to Flexflow technology, which ensures a more homogeneous pressure distribution in the cavity, the glass microsphere survival ratio is increased with even better distribution. The result is a lightweight component with no visible weld lines that meets the highest requirements for mechanical properties and surface quality.

Other typical fields of application for the Flexflow hot runner technology are lightweight yet stable injection-moulded plastic housings. At Fakuma 2018, HRSflow will be showing examples from the fields of electrics and electronics as well as general industry.

A project that has been developed together with the heating and cooling specialist Roctool, KraussMaffei and the toolmaker Flex is a cover, only 1.5 mm thick, for a 14" laptop. It is produced using a high-glass fibre-reinforced polycarbonate (up to 50% by weight) injected in cascade moulding, combining a Flexflow five-nozzle hot runner system with Roctool’s induction heating and cooling technology. The above technologies ensure highest standards in terms of functionality and appearance. In a single shot, this results in a visible surface with high-gloss and matt areas with a cost-efficient cycle time of around 50 seconds.

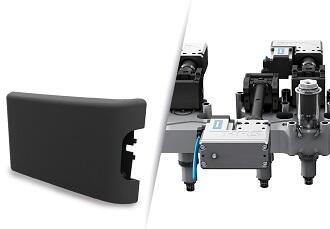

A second example of an innovative housing shown at Fakuma is a toolbox made of microcellular foam, which is characterized by its low weight. Its production is based on the FoamPro foaming process from development partner Yizumi, and a Flexflow triple-nozzle hot runner system from HRSflow with back-injection. The finished part is characterized by a high-quality, finely structured surface.