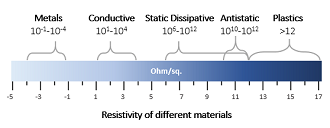

Plastic materials are electrical insulators by their own nature. This feature is usually desired in most applications but it can generate problems when the final product undergoes rubbing stress. In such conditions, the material accumulates electrostatic charges which are responsible for the “shock” received when touching an electrified object. The problem of the accumulation of electrostatic charges has increasingly become an aspect of legislative relevance thus it is regulated by various sector directives, especially for personal protective equipment for professional use such as safety shoes.

Based on SBS or SEBS and manufactured by Francesco Franceschetti Elastomeri (booth 5212, hall B5, at Fakuma 2018), Marfran TPE compounds are excellent insulators as well as all plastic materials. Nevertheless, it is possible to exhaust the build-up of electrostatic charge.

The main methods for modifying electrical conductivity in a thermoplastic elastomer can be achieved through the addition of:

- Unmixable particles of conductive materials. The electrical conductivity occurs thanks to the contact of conductive particles that create a network within the thermoplastic material. Some examples of such particles are conductive carbon black, metal microfibres, carbon nanotubes etc.

- Migrant ionic and/or hydrophilic additives. These additives migrate on the surface of the material, activating an electrical surface conductivity through time. For this reason they are easily removable so the dissipative effect is destined to decrease over time. These additives are commonly referred to as “non-permanent antistatic additives”.

- Intrinsically Conductive Polymers (ICP). The conduction mechanism is activated by a homogeneously dispersed polymer component in the thermoplastic matrix; this mechanism doesn’t depend on mechanical and environmental stresses applied to the material and it guarantees a much more stable electrical conductivity over time (permanent).

The conductive properties of the compound strongly depend on the choice of fillers and how they are dispersed inside the thermoplastic matrix but only if ICP are used, the resistivity of the object is permanent. That is why Francesco Franceschetti Elastomeri has developed three new families of antistatic TPE compounds Marfran E CD. These compounds are based on technologies that make the antistatic material both non-permanent (ionic additives) and permanent (ICP), combining the easy processability, lightness and versatility of TPE with the dissipation properties of the electrical charges.

The new Marfran E CD compounds are born as products oriented to the production of work shoes such as, for example, hospital clogs, but they can also be used in other applications by injection moulding technology.