The investigation by the Italian Competition Authority (ICA) on Husky Injection Moulding Systems has concluded. ICA ruled, unequivocally, in favour of Husky finding its conduct compliant with the law and that the elements in the underlying complaint are without merit.

As referred in a press release of Husky, this decision follows from a long and thorough investigation of Husky’s business and engineering records that lasted over two years. The ICA announced in its decision that it found no evidence of the alleged conduct set out in the anonymous complaint that would violate Italian competition laws.

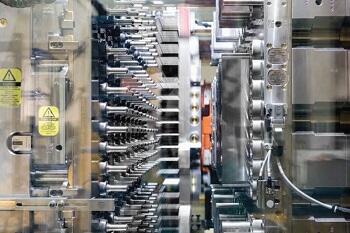

Husky’s steadfast position throughout the investigation is that its use of Mold ID technology in its HyPET HPP line of injection moulding machines is entirely pro-competitive and necessary to ensure system integrity and operator safety. Husky’s HPP technology is truly revolutionary. The operating parameters of HPP systems is entirely unique in the industry - exceptional operating capability leveraged to provide exceptional operating productivity and part quality. The safe operation of HPP machines operating at HPP-level speed requires the use of tooling (including moulds) specifically designed to withstand the extreme forces involved.

Not all Husky tooling is designed for HPP-level performance. Recognizing the market demand for machine compatibility Husky leverages the use of Mold ID technology to ensure safety and product integrity by seamlessly tailoring the operation of the injection moulding machine in line with the capability of the installed tooling, if known, and otherwise default to current market standard. This safety strategy ensures that all components of the system operate at a safe level, including when operating with Husky’s legacy tooling and third party tooling (i.e. the safety system being entirely brand agnostic).