Based on a chemical and mechanical process, with zero pollution impact, Repur is a technology to transform powders deriving from the processing of polyurethane, chipboard MDF and other recycled materials into a workable material with remarkable properties. Thanks to customized formulations of binders, it is possible to give the final product the desired physical and mechanical characteristics.

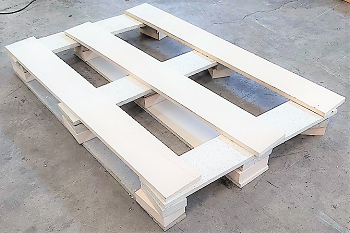

“The system can help insulation boards and slabstock manufacturers to turn powders deriving from processing into useful products”, Luca Ceresa, commercial director of Saip, explained. The first Repur line has been sold to a large rigid insulation producer and, Ceresa added, “there is a lot of scrap from rigid panel production, parts are rebated and shaped. This generates waste that Repur can turn into useful products like moulds for 3D printing, flooring, pallets, kitchen tops,

panels”.

The Repur powder recycling machine is designed to take powder and mix it with a pre-polymer and a catalyst which are then cured (temperature beetwen 40 and 50°C). The slurry is made of about 70% regrind, 23% binder and 7% hardener. In addition to polyurethane waste, the system can also use other materials which are compatible with polyurethane binder chemistry.