The latest new development at Rivi Magnetics is called Force Evaluation System (FES), and its function is to constantly monitor the working cycle of injection moulding machines for plastic materials. Therefore, it intervenes dynamically and is developed to operate with a touchscreen operator interface and tablet. It can be connected with the outside world via ethernet, and thus offers the possibility of carrying out remote assistance. Furthermore, a processor with more than one magnetic die clamping system installed can, using a tablet, view from anywhere the state of the various systems.

As Marco Landi, marketing manager at Rivi Magnetics, explained to MacPlas editors: “This system, which is supplied as an optional feature, has been developed to ensure that the processor has a greater awareness of the safety ensured by a magnetic system”.

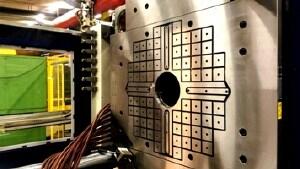

Another recent technical development concerns the combination of different types of pole in the same plate. Indeed, sometimes the rigidity of the design based on square poles means that some zones are not covered by the magnetic poles. The long pole, on the other hand, offers greater design flexibility and Rivi Magnetics can integrate the two technologies - square pole and long pole - according to the specific application needs. This is undoubtedly an advantage, as it makes it possible to obtain the best force for the given application (the photograph shows: square poles and long poles combined within a magnetic plate from the Lion series).

As regards the company’s current performance, Landi remarks that “2014 is proving to be a positive year: the fact that we are present on different markets both in Italy and abroad is helping Rivi Magnetics to grow and allowing us to hope for a gradual general economic recovery”.