Milan-based injection machine manufacturer Negri Bossi recently carried out two moulding tests for two separate customers at its headquarters in Cologno Monzese (near Milano).

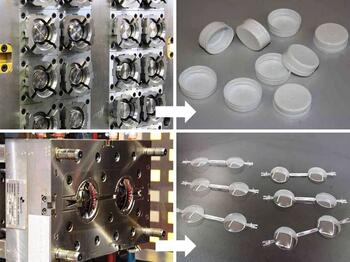

The first, for Capsol, a European cap manufacturer headquartered in Bulciago (near Lecco, Italy), was performed using a 24-cavity mould installed on a Janus 210-850 press with accumulators. The moulded article, a screw cap for use with foodstuffs featuring a diameter of 38 mm and a safety seal and produced in a cycle time of 5.5 seconds, weighs 2.6 g, and is therefore extremely light compared with other products of this kind currently on the market. Furthermore, the test highlighted the cleanliness of the mould, the repeatability of the process, and the energy savings allowed by the press.

The second test, on the other hand, concerned the production of polycarbonate lenses for spectacles. The article, which weighs 26 g and requires a cycle time of 16 seconds, was produced using a single-cavity mould installed on an Eleos electrical press with a hydraulic ejector; the press is particularly compact thanks to the use of cylinders in place of the traditional tiebars. The mould cleanliness is a particularly important feature that makes this system suitable for medical and technical applications.