Developed by Gefran for laboratory extrusion lines and compounding, the new compact control system eXtru+ comes ready to use; it is fully programmable and features built-in advanced technological functions. The extrusion of plastic materials is a process that demands flexibility, precision and efficiency. This new system makes it possible to monitor, view and manage the whole process in a very simple and effective way.

The system is also a response to the growing demand for efficient temperature control. Its efficient energy management and energy-saving functions, linked to correct use of the thermoregulation zones during the startup and maintenance phases, integrate optimally with extremely advanced diagnostics and the possibility, through different services that can be activated on the Ethernet port, of rendering the system “remote”.

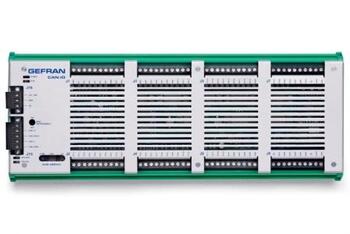

The flexibility of the system is guaranteed by the adoption of CANopen, an open and standard communication protocol, which makes it possible to integrate third-party products, and also by the possibility of partly or completely modifying the application supplied with the system. Precise control, in particular precise thermoregulation, is ensured by the powerful PLC which manages all the control loops, the synchronisation of the motors, the alarms and the melt pressure, storing the data and alarms for quality control purposes. Finally, the 7-inch display and intuitive graphics ensure easy and immediate use of the system.

Every aspect of the application software supplied with the system, based on standard programming technologies (IEC61131-3), has been verified, tested and documented. This software covers all the typical needs of extruders. Furthermore, the graphics and the PLC code are customisable, if necessary. The time-to-market is extremely short and the customisations are quickly and easily implemented.