Among the six finalists of the MD&M West Innovation Prize, a contest dedicated to innovation in the medical sector, there is also an Italian manufacturer, Gimac, partner of the American company Syneo in the development of a fully automated system for the coating, during the extrusion process, of cable guides for the medical industry. The winner will be selected during the MD&M fair (Medical Device and Manufacturing) West, one of the most important in the world for the medical sector, running in Anaheim, California, from February 9 to 11.

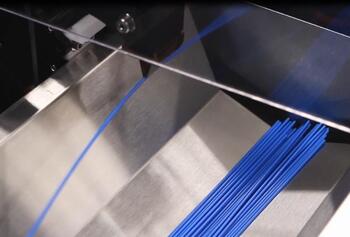

Gimac created a system with true closed loop motion control for ultra-precise indexing of material. Syneo claims the system, coupled with its guidewire pick and feed technology, turns a difficult, labor intensive task into a fully automated process. A user can load hundreds of nitinol or stainless-steel cores, typically with distal ends centerless ground with a fine taper, into a the input bin of the feed system. The system will pick and feed the parts continuously through the extrusion cross head. The system preheats cores prior to extrusion to promote adhesion, measures the input and output diameter of parts, precisely adjusts core velocity through the cross head to control coating thickness, cuts the parts to separate the discrete lengths, inspects the outside diameter on 100% of the wires, and bins the material pass/fail based on laser micrometer feedback.