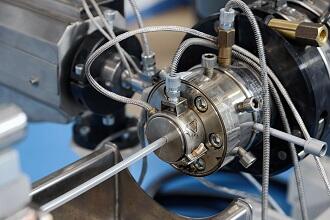

Bausano & Figli recently optimised its line for the extrusion of medical tubing, in order to improve its performance and reliability. The use of new technologies and the quest to find innovative solutions capable of meeting quality, precision and dimensional control requirements become even more fundamental when these are destined for the medical sector.

The line is equipped with a new coextrusion head to facilitate and allow greater rapidity of dimensional change in the production of flexible PVC tubes with coloured or radiopaque lines. Another new feature is the stainless steel tank with double air gap that, thanks to the insulation provided, avoids the formation of condensation. Furthermore, upper anti-contamination caps allow it to be used in the grey room, as well as in the clean room.

The external diameter and the thickness of the tube

are measured using an improved system that measures at 4 points and displays

the results on a 15” screen, while

deviations from dimensional tolerances are signaled by automatic alarms. In

addition, automatic feedback on the vacuum system allows control of the

diameter and possible ovalization of the tube.

The external diameter and the thickness of the tube

are measured using an improved system that measures at 4 points and displays

the results on a 15” screen, while

deviations from dimensional tolerances are signaled by automatic alarms. In

addition, automatic feedback on the vacuum system allows control of the

diameter and possible ovalization of the tube.