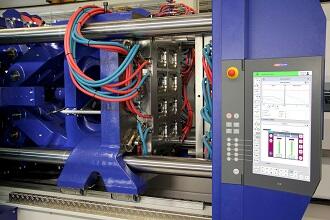

Under the motto “Be Smart”, Wittmann Battenfeld is showcasing its first all-electric high-speed machine model at the K 2016 in Düsseldorf. With the new EcoPower Xpress 400/1100+, the manufacturer introduces the development of a high-speed, all-electric machine model primarily geared to the requirements of the packaging and thin-wall industry. The highly dynamic drive axes for injection as well as closing and opening of the EcoPower Xpress are designed for fast movements and ultimate control accuracy. Moreover, extremely high energy efficiency is achieved by using servo drives. EcoPower Xpress stands for high output with optimized utilization of energy, thus making a vital contribution to sustainability in plastics processing.

The EcoPower Xpress 400/1100+ exhibited is the first size of this machine series, which will be available from fall 2017 onwards with clamping forces ranging from 2100 to 5000 kN.

At the K

show in Düsseldorf, the EcoPower Xpress will be on display with a Wittmann W837

IML system. On the EcoPower Xpress 400/1100+, lids made of PP will be

injection-molded within a cycle time of 4.7 seconds with an 8-cavity mold

supplied by Greiner Packaging, Austria. The W837 side-entry robot from the

company inserts the IML foils, removes the labeled lids, subsequently presents

them to an integrated camera for quality inspection and then separates the good

parts from rejects. The IML system comes with compact design and a facility for

fast foil change.

At the K

show in Düsseldorf, the EcoPower Xpress will be on display with a Wittmann W837

IML system. On the EcoPower Xpress 400/1100+, lids made of PP will be

injection-molded within a cycle time of 4.7 seconds with an 8-cavity mold

supplied by Greiner Packaging, Austria. The W837 side-entry robot from the

company inserts the IML foils, removes the labeled lids, subsequently presents

them to an integrated camera for quality inspection and then separates the good

parts from rejects. The IML system comes with compact design and a facility for

fast foil change.