Arburg presents "smart" machines, processes and turnkey solutions for efficient plastics processing at Fakuma 2017 from October 17 to 21. "As a cofounder of Fakuma, we are proud to have been part of the event from the outset, and to be the largest exhibitor at the 25th edition of this successful trade fair in 2017," says Michael Hehl, managing partner and spokesperson for the Arburg Management Team. "With ten machines on our own stand and eight more on partner stands, our focus this year will again be on 'smart' and practical solutions for production-efficient plastic parts manufacturing. With over 30 years of experience in networked and flexibly automated production, we also offer everything an injection moulding machine needs in the context of Industry 4.0 - from the “smart machine” and the Arburg Als host computer system to smart services".

The German manufacturer displays:

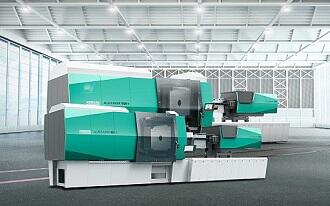

- injection moulding machines: AllRounder 1120 H and AllRounder 920 H in the new Arburg design and the new Gestica control system;

- solutions for Industry 4.0: online integration of processors requirements into the injection moulding process and flexible production in single-unit batches;

- high-end applications: LSR/LSR injection moulding, packaging technology and more;

- freeformer: first ever processing of PP and support material armat 12.

In particular, after Arburg heralded the future of injection moulding with the hybrid AllRounder 1120 H at the K 2016, the next step now follows: at Fakuma 2017, a hybrid AllRounder 920 H (introduced during a press conference on October 17) is launched in the new design and with the new Gestica control system. The two pioneering large scale machines with clamping forces of 6,500 and 5,000 kN are the highlight of the Arburg stand. The AllRounder 1120 H with a clamping force of 6,500 kN and size 4600 injection unit produces a folding step stool weighing 1,092 g. Eight individual PP parts are produced in a cycle time of around 60 seconds and assembled to form the finished step stool. The AllRounder 920 H with a clamping force of 5,000 kN and a size 4600 injection unit produces a 710 g housing from glass-fibre-reinforced PA 6 in a cycle time of around 75 seconds.

The Gestica

control system is based on all the advantages of the proven Selogica, with which

it is fully compatible. New practical features include, for example, a full HD

screen, a rotatable and height-adjustable control panel and smart operation via

the Easyslider. In addition

to its aesthetic appeal, modern colour scheme and shape, the design offers

enhanced functionality and significantly improved ergonomics. The practical

extras include, for example, a large safety door and integrated colour-variable

LED light strips, which indicate the operating status.

The Gestica

control system is based on all the advantages of the proven Selogica, with which

it is fully compatible. New practical features include, for example, a full HD

screen, a rotatable and height-adjustable control panel and smart operation via

the Easyslider. In addition

to its aesthetic appeal, modern colour scheme and shape, the design offers

enhanced functionality and significantly improved ergonomics. The practical

extras include, for example, a large safety door and integrated colour-variable

LED light strips, which indicate the operating status.