RadiciGroup

is exhibiting at Chinaplast 2019 through Radici Plastics Suzhou and focusing on

four strategic markets for its high performance polymers business area: automotive,

electrical/electronics, water and heating systems, and transport.

RadiciGroup

is exhibiting at Chinaplast 2019 through Radici Plastics Suzhou and focusing on

four strategic markets for its high performance polymers business area: automotive,

electrical/electronics, water and heating systems, and transport.

“We have just increased our production capacity”, pointed out Alberto Sessolo, CEO of Radici Plastics Suzhou, “aiming primarily at enhancing our flexibility in order to better satisfy our customers, also for special application needs. In particular, we have been following the evolution of electric cars very closely, and we are working on a number of very interesting projects in collaboration with both local and global OEMs. Our objective is to continue to grow, despite the fact that the world market, including China, started sending out signals of a slowdown from year-end 2018 to the beginning of 2019. In any case, we are confident that we are going to achieve our objectives”.

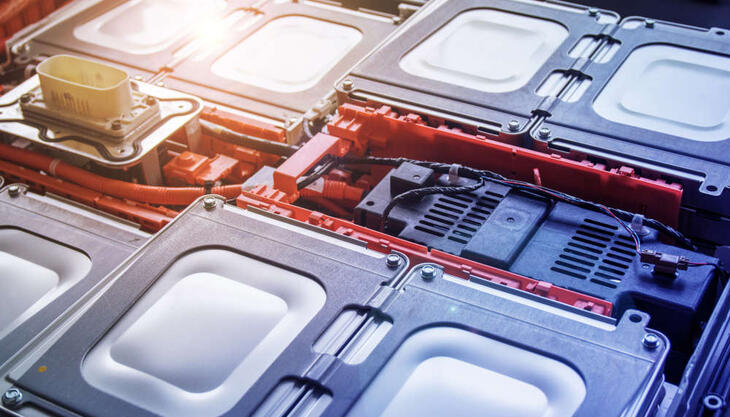

Regarding products, markets and applications, Erico Spini, global marketing manager of RadiciGroup High Performance Polymers, explained RadiciGroup’s focus at Chinaplas: “Today China is the world leader in the development of new vehicles with electric engines. For this market, RadiciGroup offers materials specifically developed for applications on electric and hybrid cars”.

The range of products for this kind of application include PA 6 and PA 6.6 engineering polymers, such as Radiflam HF and Radiflam FR, halogen- and phosphorous-free products with excellent flame-retardant characteristics, which are used primarily for battery system components and power management units (e.g., inverters). What is more, materials developed for charging plugs and sockets, which must ensure durability and safety. In an electric car, the heating and air-conditioning management system must be especially efficient to optimize battery usage and the working of many other parts. Thus, besides traditional polyamides, RadiciGroup offers long molecular chain polyamides for applications requiring enhanced performance: biobased PA 6.10 (Radilon D - PA 6.12 Radilon DT) to PPA (Radilon Aestus T1) and PPS (Raditeck P). These are polymers for engineering applications with very high chemical resistance and, in the case of Raditeck P, excellent intrinsic flame resistance, as well.

“We are working on new flame-resistant products”, Spini continued, “to be used for components under electrical voltage, which, for safety considerations, must be orange in colour. The colour must remain stable during long exposure in unfavourable conditions and high temperatures”.

Safety is the keyword that characterizes RadiciGroup brand products for the electrical/electronics sector: an expanding range of UL-approved products that safeguard the environment and are formulated to give components a long service life and enhanced safety. These materials feature excellent properties such as high flame resistance, insulation, UV resistance and more. Among the most important electrical segments making use of Radilon and Radiflam are power distribution systems and industrial control systems, where components such as plugs, sockets, switches, connectors and others are needed.

The water, heating and sanitary systems market has experienced considerable growth driven by new civil and industrial construction. RadiciGroup High Performance Polymers has released PA 6.6 products (Radilon A versions suitable for drinking water contact) and more recently PA 6.12 products (hydrolysis resistant Radilon DT). For more critical applications where parts are in contact with water at temperatures of up to 85°C, RadiciGroup offers KTW-certified PPA Radilon Aestus products.

“Transport is another attractive sector for us, considering the strong development China is experiencing”, Spini concluded. “Our high-viscosity and glass-fibre reinforced polyamide-based materials are used to make components, such as rail fastening systems, insulating plates and other structural parts, for which good performance characteristics are an essential requirement”.