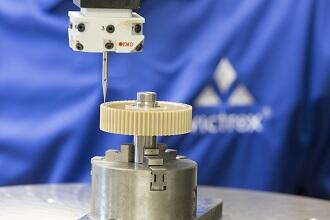

Victrex has achieved a new milestone for its automotive offerings. Its gear design and manufacturing facility in Grantsburg, Usa, has received the IATF 16949 certification, proving that the necessary systems and capabilities in line with Tier1/OEM needs are in place. At the international K 2019 tradeshow in Düsseldorf, gear solutions will also be one focus at the Victrex booth.

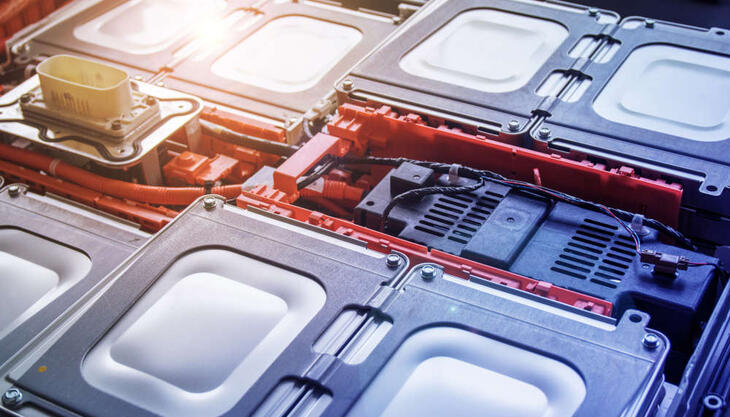

Victrex PEEK has been used in auto gears for decades but since 2015, Victrex has extended its material expertise to the design, development and manufacture of gears, to offer a fully integrated and highly innovative approach to thermoplastic PEEK gear solutions. Enabling Tier 1/OEM customers to work with one partner from concept to commercialisation, the company supports the development and testing of high-precision Victrex HPG-based gears, as well as manufacturing these gears as a component for integration into larger systems, e.g. within the engine, transmission, pump, actuator and chassis.

Victrex´s gear solutions include high-precision gear design, prototyping, testing and manufacturing capabilities using Victrex HPG polymers. Compared to traditional metal-based gears, Victrex HPG-based thermoplastic gear solutions for ICE and Electric Vehicle Platforms offer decisive benefits such as improved NVH (noise, vibration, harshness) performance as well as enhanced efficiency reducing carbon dioxide and system cost reduction.