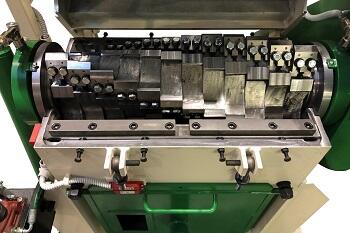

What to do to reduce noise, dust and energy consumption when recycling scrap directly on the processing machine? For this application Adler has developed a cutting system which, by exploiting the combination of helical scissor cutting and the multiplicity of cutting edges, has achieved the desired result.

This application, for a French multinational in the blow molding sector, has led to the continuous grinding and reuse of necks and bottoms and related 1-liter PP bottles without the problem of dust. By using a low speed transmission system and the helical cutting system, consumption has greatly decreased, passing from 6-7 kW/h to the current 3-4 kW/h; the dust drops to about 100 ppm. In addition, the multi-blade cutting system has reduced noise to about 60 dBA empty machine, and at work to 70-73 dBA.

The machines are available in several sizes from 600 x 300 mm up to 1,500 x 500 mm and are suited to all grinding applications on the machine in line and off line.