The two coextrusion solutions supplied by battenfeld-cincinnati in 2019 proved so perfectly satisfactory to the modern Polish system manufacturer of door and window profiles from the very beginning that they immediately placed repeat orders for several more. With the space-saving piggy-back models consisting of main extruders and coextruders, Decco based in Suwalki, North-Eastern Poland, extends its production equipment to a total of 20 lines. The Austrian extruder specialist battenfeld-cincinnati is currently installing the last models from this year’s major order.

“We are so pleased with the support and the machine solutions from battenfeld-cincinnati that we have been working continuously with extruders from Vienna right from our startup in 2004 and have kept on buying equipment from them ever since”, said Piotr Domaszewski, Managing Director of the Polish profile manufacturer. “The high-performance level of the extruders and their mature process technology support the production of high-grade, durable profiles for some 350 customers in 30 different countries”.

Again and again, Decco is extending its product portfolio with additional modern, innovative profile systems to meet its customers’ specific circumstances and needs in terms of both design and performance. Here, sustainability and recycling are vital aspects. This is precisely why the Polish plastics processor has now decided to acquire coextrusion solutions which enable the production of multi-coloured designs and the integration of recycled material in the middle layer. To this end, Decco uses not only its own production scraps, which are collected and shredded, but also bought-in recycled material in the form of PVC regrind.

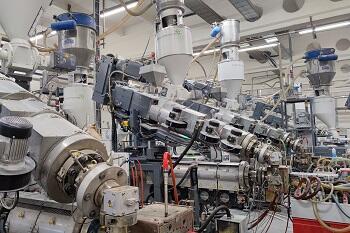

Especially in situations of limited space on the production floor, the piggy-back solution designed by battenfeld-cincinnati provides a space-saving alternative. In all coextrusion solutions recently delivered to Decco, a twinEX 78-34 with an output of up to 290 kg/h functions as the main extruder, combined with a conEX NG 65 as coextruder. The conical twin screw extruder with up to 250 kg/h output is mounted on top of the parallel extruder, so that floor space is required only for the latter. In addition to saving space, the piggyback configuration offers further cost advantages through a common control cabinet and easy operation, together with high energy efficiency. The integration of tooling is simple and variable thanks to the flexible frame structure of the co-extruder.

“The space-saving solution was certainly a buying incentive for us. But at least just as important are the energy efficiency and performance of the two extruders, which guarantee economical manufacturing of high-quality profiles”, Piotr Domaszewski commented. So, the twinEX parallel twin screw extruder with 34 D processing length produces excellent results especially in PVC processing with high output, thanks to its long processing unit and optimized screw geometry.

The Intracool screw cooling system and the Air Power Cooling system inside the barrel provide accurate temperature control and thus high melt and product quality. The latter is also due to the conEX conical twin screw extruder of the new NG generation. Its intelligent process technology concept with an extended preheating zone and optimized screw design ensures high output rates with low shear input. In addition to low machine wear, the well-balanced ratio of mechanical and thermal energy input into the melt enhances the possibilities for processing a great variety of different materials with a single screw configuration.