New rotary stretch-blow molding machines from PET packaging technology specialist Sipa are faster, more versatile, and run even more efficiently than their predecessors. The SFR EVO3 model range is available now in versions with 6, 8, 12 and 16 cavities. The new 10 cavity platform and larger units, with 20 and 24 cavities, will debut later this year.

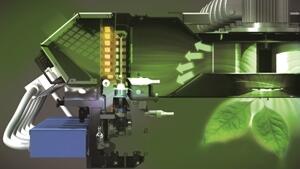

Special features include new designs in the clamp unit and in the cams that help the SFR EVO3 achieve a maximum output rate of 2250 bottles per hour per cavity, putting it on the front line of the grid with the competition. A new blowing valve block is more compact than before, and has 35% less dead air volume.

SFR EVO3 users also have the option of taking advantage of mechanical compensation in the blowing process. In traditional pneumatic compensation, the total stroke is made with high pressure blowing air, but in Sipa's the new mechanical system, high pressure blowing air is used only on the final fraction of a millimeter. This leads to a massive reduction in air consumption, particularly with smaller bottles.

"Green" ovens on the SFR EVO3 are big energy savers. Compared to earlier generations of oven, they reduce electrical consumption by up to 40% while keeping process conditions stable, thanks to the use of new lamps and special materials and coatings for the reflectors.

Also available for the SFR EVO3 are electrically driven stretching rods. This brings much more versatility in fine-tuning the process compared to pneumatic drives. Stretch rod timing, speed, acceleration and distance can all be controlled with ease and flexibility from the machine controller (HMI). Electric drives are also perfect for Sipa's Sincro Bloc integrated blowing and filling system, to match the blowing operation to different filler speeds.

With electric drives, there is no need for the stretch rod decelerator and the stretching cam, which among other things helps shorten product change-over times. The electric stretching system on the SFR EVO3 also has a 'smart' self-learning procedure to identify preform/bottle dimensions.

The SFR EVO3 has a new standard mold changeover system that is quick and easy to use. A new optional feature that Sipa is currently perfecting should make mold changes even more efficient.

Increased efficiency is also built into the molds themselves. The SFR EVO3 is much easier to convert from production of hot-fill to cold-fill containers because, while the heating circuit remains in the shell holder, the cooling circuit is now built into the cavity. Only a simple cavity change is required to switch from production of one type of container to another, while the shell holders remain in place.