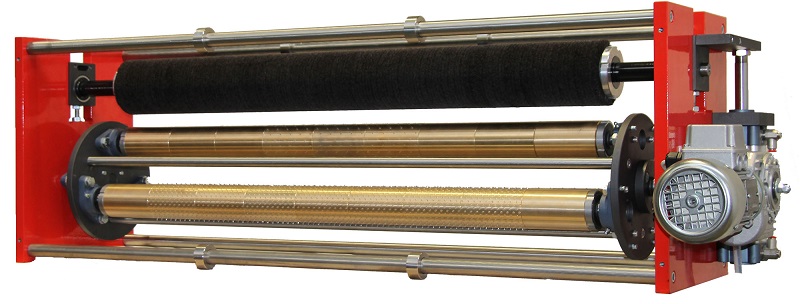

The new drum microperforator unveiled by Exact at the K 2016 show has been developed and designed for those applications requiring frequent and rapid changes in perforation, and is characterised for being simple to operate, robust, and easy to install.

The machine is equipped with multi needle rollers, which rotate as necessary, each of them offering various perforation densities, sizing and patterns. The rotation system is managed by a remote control, reducing working times, while tapered needles are fixed onto numerous bronze sleeves, each measuring 100 mm in width.

Simple substitution of the bronze sleeves enables various perforation diameters and densities, allowing for different perforation patterns. The shaft is driven by the movement of the film, while the penetration of the needles into the material is regulated by a simple mechanism which allows for further slight variations in the diameter of the hole piercings.

The microperforator can be customized based on individual processing needs.