The 2017 has started with an unique possibility for all WM

Thermoforming Machines customers: in January, during week two and three, at the

company headquarter in Stabio (Switzerland) complete in-line plants and the vacuum

and pressure thermoforming machines are exhibited in running mode.

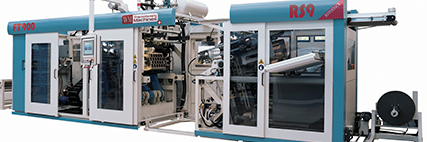

The Intec FT 900/3 with Rotostacker RS9 is a fully automated system that transform the plastic pellets into final product, with integrated sleeving and boxing process. WM is a specialist in this application and can count more than 100 in-line plants sold and operative all around the world.

The FT 900, also equipped with Rotostacker RS9, is a pressure forming-punch

and die machines with lower tilting plate studied to fulfill the customer’s

demand for medium and high productions of disposable cups, dairy containers and

tubs that require closed cutting tolerance, high product quality fully

automated processed.

The FT 900, also equipped with Rotostacker RS9, is a pressure forming-punch

and die machines with lower tilting plate studied to fulfill the customer’s

demand for medium and high productions of disposable cups, dairy containers and

tubs that require closed cutting tolerance, high product quality fully

automated processed.

Last but not least, vacuum and pressure forming four stations

with additional holes punching press and in-line steel rule cutting, the FC 780

E HP Speedmaster Plus can process all thermoplastic materials like PP, PS,

APET, CPET, PS, PLA, OPS, EPS, PVC, guaranteeing an optimized efficiency and

higher performance with any material. One of the most important features is the

possibility to work with all thermoforming mould technologies such as male or

female moulds as well as positive and negative forming moulds.