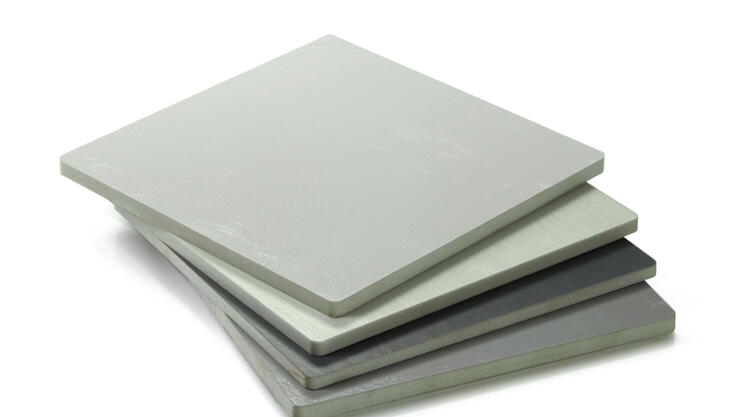

The new special polyamides for the extrusion market are the next frontier for RadiciGroup Performance Plastics. Today the Radilon product range, as well as technopolymers that offer improved resistance to high temperatures (Radilon A HHR and Radilon XTreme) and reinforced materials for metal replacement (Radilon A RW and Radilon S URV high fluidity), includes long-chain polyamides: Radilon D based on PA 6.10 from partially renewable sources, Radilon DT based on PA 6.12 and RADILON CD that are copolymers PA 6.10/6.6 also being partially bio-based.

These are polyamides with specific chemical-physical characteristics, whose properties can be adapted to suit the needs of the end customer. An innovative approach that RadiciGroup Performance Plastics is able to provide, thanks to its synergies with the Group’s other business areas - in particular with the Specialty Chemicals Area - with the aim of meeting the increasingly stringent market requirements, in terms of performance and flexibility.

So what are these special products main applications in the extrusion sector? PA 6.12 is used in the personal care industry (e.g. filaments used for toothbrushes or mascara applicators) thanks to its bend recovery characteristics, flexibility and chemical resistance. When properly formulated with compounding technology, this polyamide can also be used in pipe manufacturing (e.g. petrol ducts, oil & gas and air pipes) where, in addition to the chemical and mechanical resistance, the final product transparency is valued in respect to those manufactured with traditional polyamides (PA 6 e PA 66).

PA 6.10 is usually used for the production of monofilaments for industrial applications thanks to its unique chemical resistance and (bend recovery characteristic which increase its durability; alternatively, it can be used for manufacturing pipes suitable for transporting petrol in fuel lines, mainly for its inherent burst strength).

Copolymers 6.10 and 6.6 are ideally suited for manufacturing packaging, films and wraps, also for the food industry where transparency, thermoformability and water vapour barrier properties are required. Thanks to the technologies provided by RadiciGroup Performance Plastics, a metal detectable material has been formulated using this polymer, which is used to manufacture brushes for cleaning devices in the food industry. The specific formulation allows for the detection of plastic residues, after cleaning objects that are intended to come into contact with food. This is a feature of utmost importance in terms of health and safety and that once again, shows how RadiciGroup is an innovative supplier who is able to meet the most demanding needs of its customers.

“By

introducing this new range we aim at implementing a diversification process in

the market, that is possible thanks to the vertical integration of our Group.

The Novara chemical plant is our “internal” trusted partner for developing

products in line with the different expectations of our customers”, said Enrico

Simonato, RadiciGroup Performance Plastics extrusion market manager.

“By

introducing this new range we aim at implementing a diversification process in

the market, that is possible thanks to the vertical integration of our Group.

The Novara chemical plant is our “internal” trusted partner for developing

products in line with the different expectations of our customers”, said Enrico

Simonato, RadiciGroup Performance Plastics extrusion market manager.