Bandera’s business fellowship with an important company located in The Netherlands started in 2012 and has continued up to the current time with the supply of four rigid film and sheet extrusion lines for thermoforming addressed to food packaging and industrial applications. Installation of the fourth and most recent one, a specially conceived line, called Agility Line, has been just executed with successful start-up.

The Agility Line is one of the latest Bandera developments, conceived to meet the requirements of customers who need a compact line, designed for optimization of special frequent changes of production, in order to maximize its handling efficiency while running different formulations. It is pre-assembled on a platform, suitable for installation even in limited floor space conditions and can be dedicated to short production campaigns with limited scraps.

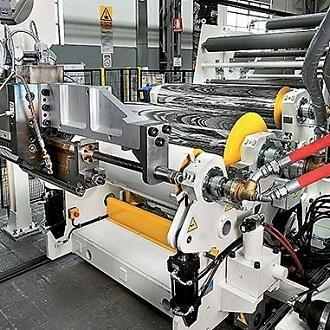

This rigid film extrusion line is dedicated to the processing of PET and is fitted for single layer extrusion, but foreseen for future installation of a coextruder. It features an output of roughly 600 kg/h and a maximum net width of 860 mm. A further characteristic of the line is the Bandera patented dryerless technology, with highly vented HVTSE 2C70 (52 L/D) corotating twin-screw extruder, capable of processing up to 100% recycled raw materials, equipped with double plate continuous filtration system.

It is also equipped with the following units:

- raw material handling and conveying system combined with “loss-in-weight” gravimetric dosing system directly mounted on extruder platform;

- single manifold flat extrusion die, with internal deckling system for fast film width adjustment;

- compact unit including horizontal cooling and polishing roll stack, thickness control system, and combined haul-off/ silicone coating device;

- grinding unit for edge trims, allowing the direct in-house recycling of the skeleton waste produced during the extrusion process;

- special, compact, fast, automatic revolver system suited for single-reel winding, designed to match the production requirements of a specific series of thermoforming sizes;

- integrated power and control HMI section.