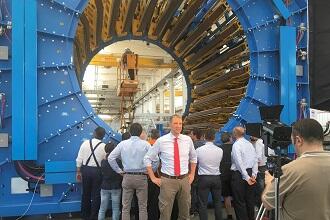

For today’s market of HDPE pipes for pressurized media - increasingly focused on large diameters and wall thicknesses - and profiting from its experience of over 50 years in the development of machines downstream to pipe extrusion lines, Sica has developed the new multi-caterpillar P3500/24Plus haul-off, which is capable of pulling HDPE pipes with diameters of up to 3.5 meters.

While being able to reach a pulling force of up to 900,000 N thanks to its 24 caterpillars, this haul-off ensures low energy consumption by adopting high-performance mechanical transmissions, as well as reduced maintenance. To cope with the oily behavior of polyolefin, all the rubberised pads of the caterpillars are made with new special compounds: their specific anti-wear properties combined with high contact friction levels ensure an effective gripping action, in addition to the long lifetime of the pads themselves.

To avoid malfunctions on lines of this size, the new haul-off has been equipped with a control software with specific functions, and special devices to constantly check the efficiency of the machine during the pulling action, such as the redundant encoders for an accurate monitoring of speed, and digital pressure switches for the continuous monitoring of operating pressures and the tension forces of caterpillars. In addition to this, the individual control of each caterpillar greatly improves the versatility of the haul-off in spite of its huge size, allowing the handling of a particularly large range of diameters (from DN2000 to DN3500).

The sturdy supports for pipes handled with electrical devices - placed at both the entry and delivery sides of the haul-off - complete the standard equipment of the machine, ensuring a simple and secure management of pipes despite their extreme weights and sizes.