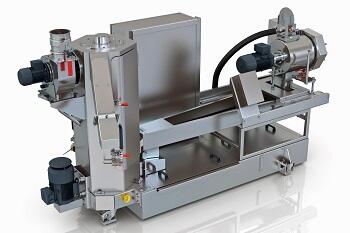

New-generation BKG 1000 water-ring pelletizer

A new-generation water-ring pelletizer (WRP) from Nordson Corporation provides uniform polymer flow, efficient heating, quick die plate change, and low dryer noise, enabling compounders and recyclers to increase productivity and enhance pellet quality. The new BKG WRP 1000 pelletizer represents an advance over previous WRPs and includes improvements adapted from the company’s widely used BKG underwater pelletizers (UWPs). As with other WRPs, the new system provides substantial advantages over strand pelletizers in that it is more compact, generates less dust, is not affected by strand breaks, is more capable of automation, and yields pellets of more uniform shapes and sizes.

In the WRP process, pellets are dry as they are cut from the polymer melt at the die plate, then are flung into a ring of circulating water, where they undergo initial cooling. Further cooling takes place in a chute that transports the pellets to the dryer. Prior to drying, a major part of the water and any agglomerates are removed.

Key benefits provided by the new BKG WRP 1000 system include:

- rapid die plate change: the die plate has a split design, with separate heating flange and easily exchangeable insert; the design makes possible rapid color changes and easy cleaning;

- efficient die plate heating: the die plate is heated electrically with heating cartridges and is designed for uniform polymer flow in the die plate holes;

- efficient and low-noise pellet drying: the centrifugal drying system is adapted from the well-known pellet dryer used for BKG UWPs and guarantees low moisture levels of the pellets; noise does not exceed 85 dB, and the dryer is easy to maintain and to clean with good access through the two large doors;

- automated process control option. Besides a pre-wired version without control system for system-integrators, a stand-alone PLC-based system is available for an easy, independent operation and an easy upgrade of existing lines.

Maximum operating parameters for the BKG WRP 1000 system are: throughput of 1,000 kg/h; melt pressure of 210 bar; and melt temperature of 320° C. The pelletizer can be used to process a wide range of olefin and styrene polymers and copolymers with good melt strength and density up to 1.5 g/cm3, including moderately filled materials. Die plates are tailored to the specific material to be processed.