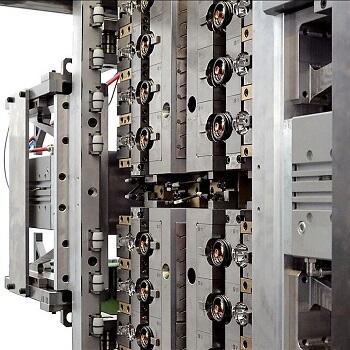

With over fifty years of experience in the creation, construction and design of moulds for different sectors, including food and beverage, cosmetics, home care, automotive, pharmaceutical and healthcare, the Italian Gefit, always looking for innovative solutions, has decided to replace the hydraulic or pneumatic movements with electric drives on its molds with unscrewing system.

The Moulds Division, a reference point for the packaging and closures market, for high quality moulds with low cycle times, has joined forces with the Automation Division, which regularly uses electrical drives on its assembly lines.

The devices with electrical unscrewing are technically more innovative and offer several advantages: in addition to greater ease of assembly and less noise, the absence of mechanical drives allows for a considerable reduction in maintenance interventions and problems due to wear.

The electric drives also make it possible to increase the efficiency and performance of the moulds, reducing cycle times, thanks also to the more precise control of the screw position and stroke, with the consequent optimization of processes in each phase.

This electrically operated system, used for unscrewing molds but also applicable to flip top closures in the machine, allows for more accurate and repeatable movements.