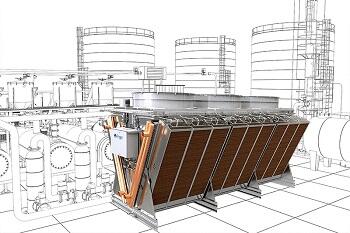

The imperatives of sustainable development and ever higher energy efficiency of industrial plants and activities constantly require the development of new solutions. By building on the vast experience in process cooling and using the latest technologies available today, Frigel Group is introducing the brand-new LDK range of adiabatic coolers. This is the first step on the way of the extension of the proven Ecodry platform, in order to replicate its success in new industries and applications.

“We deliver the new LDK range now, which is very close to our hearts at Frigel, The targets we set for ourselves were easy to identify with. We had to engineer a solution which will help our existing and future customers to stay ahead of their competitors through increased operational efficiency on the one hand, by delivering this at the least water consumption on the other. We had a strong foundation to build upon, but this time we raised the stakes by creating a product to be able to meet a higher capacity demand in challenging industrial environment”, Duccio Dorin, Frigel Group CEO, states.

Adiabatic cooling plays a key role in technology conversion, especially related to cooling tower replacement. This is driven by many factors, including the underlying strategies to improve overall efficiency, the growing desire of the business community to use ‘green’ solutions, as well as hygienic safe operation.

“The operational parameters of the LDK provide a significant advantage compare to other solutions. Its modular design will be an excellent fit for a wide range of requests both in the industries we have been serving as well as in new areas. We are proud to engineer a more efficient and sustainable industry”, Dorin adds.