At K 2022, Brüggemann presented three new additives for improved stabilization of polyolefin recyclates. These additives result in recyclates with very good mechanical and processing properties, making the need for the addition of virgin material unnecessary. All Bruggolen R grades are supplied as dust-free additive blends in compacted granule form for easy and homogeneous distribution.

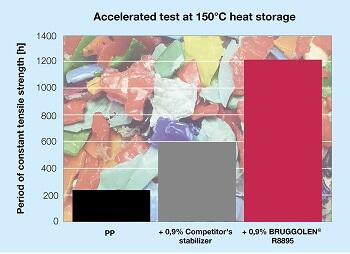

Two of the new stabilizers are intended for polypropylene recycling. Bruggolen TP-R2090 can be used to recycle post industrial and post consumer waste, whereas Bruggolen TP-R8895, through its increased acid scavenger content, is especially suitable for recycling polypropylene from battery cases. Both additives result in recyclates of quality that cannot be achieved via conventional re-stabilization.

For polyethylene recycling, Brüggemann has developed Bruggolen TP-R2162, which also contains the new repair technology and is particularly suitable for LLDPE recyclates used in film extrusion. Here, the repair mechanism results in film with increased initial mechanical strength and a significantly reduced number of defects. Laboratory tests, for example, show an increase of around 25% in tensile strength and 10% in elongation at break, even at minimal dosage levels of 0.3%.

These outstanding properties of the polyolefin recyclates are made possible by a specially developed technology. For the first time, it is possible to repair defects to the molecular chains that occur during processing and subsequent use and which impair quality. The recyclate is not only protected from further damage by re-stabilization, but, by repairing the polymer chains, the resultant mechanical strength more closely matches that of virgin polymer.

With the newly introduced Bruggolen R grades, Brüggemann complements its broad portfolio of additives for mechanical recycling of polyamides. These include long-term heat stabilizers, process stabilizers, flow improvers, reactive chain modifiers, nucleating agents and other process auxiliaries.