An innovative molecular nanotechnology process applied to polystyrene is the outcome of a collaborative effort between the University of Milano-Bicocca (specifically, the interdisciplinary team led by Piero Sozzani, professor of industrial chemistry) and the University of Kyoto. The project has led to the development of a new atactic polystyrene that is stronger, lighter and cheaper than steel or carbon fibre. Indeed, a car body made of this material promises to be strong enough to stand up to the weight of an elephant!

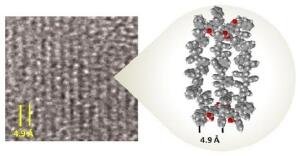

The method commonly used to prepare polystyrene involves stretching the polymers to align and lengthen them. However, this process is reversible and not always perfect. The new molecular method instead aligns the polymers as they are created so that the alignment is incorporated into their molecular structure. The polymer chains are held in position by molecular tweezers, i.e., nanoscale clips that ensure long-term stability to the orderly molecular structure.

The resulting material, obtained in crystalline form via cross-linking, exhibits high mechanical strength precisely due to its structure: the stable alignment of the polymer chains allows the material to support loads of up to 6-8 tons per square centimetre, as opposed to 1.5 tons for carbon-fibre composites. Another great advantage of this innovative material with respect to carbon fibre or the more common aramid fibres is that it costs at least ten times less to produce.

Sozzani is very satisfied: "With this discovery we finally have the ability to employ a lighter, stronger and more economical material in a range of different industrial applications: from the automotive and naval industries to hi-tech and aerospace."