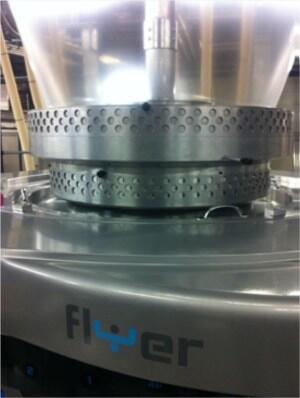

At its stand (A74, hall 10) at K 2013 Syncro will unveil the latest high performance automatic air ring, the Flyer. The latest design includes a new patent pending double auto profile control technology based on both volume and temperature control. The new flyer will guarantee over an 80% improvement of the profile error from the starting value. Due to the triple stabilizer, it can now achieve even higher outputs with enhanced bubble stability.

The company will also unveil the innovative optical gauging system, Optylayer. This new technology works in sync with the Combyscan gauging system to discriminate different layers in a complex barrier structure. Based on Near Infra Red technology, this new sensor offers significant benefits for users who need to monitor a single layer of a complex barrier structure on line.

Moreover, in response to markets needs, Syncro has developed a non-contact capacitive gauging system, the Skymex. Based on two capacitive sensors working together and a controlled air cushion, it can also be installed on the new rotating unit eaSYroto 360, which can run continuously covering 360°.

In addition, Reifenhäuser will be running a lab line live at their factory in Troisdorf (Germany) with a special version of the eaSYbatch for high temperature materials. This same blender will be running in the SML stand at the show. Dolci Extrusion will be running a blown film line with the Flyer high performance auto air ring and also an optical non-contact gauging system, Optymex. The line will have a loss-in-weight continuous gravimetric system, Sydos, featuring a complete supervisory system, Syntrol, and the control Syibc. This line also has the latest technology from BMec (Syncro's sister company), a primary and secondary calibration basket along with the complete oscillating haul-off. Finally, Colines will be demonstrating a cast line with the Optyscan optical scanner.