The processing of polymers brings its share of problems that can slow production, increase costs and reduce product quality. Such problems take place during colour and material changes mostly and include faded/mixed colours, black specks, material losses and time waste. Only the use of a strong and effective purging compound can reduce those problems and greatly improve production efficiency.

In order to solve these problems in the most effective way, after months of R&D activities, the Swiss-based company Ultra System (booth M57, hall W1/Swiss Pavilion, at the trade fair Chinaplas 2016) has developed a new, updated product range that adds itself to the existing Ultra Plast grades: the Qualipurge CS.

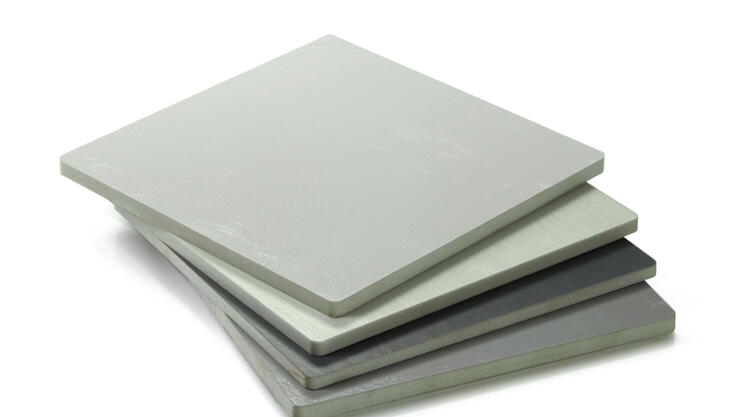

The new product line includes grades that can be used for all polymers and on all machines. These are PO-CS and POE-CS (both for polyolefins), High-CS (for all transparent materials, such as polycarbonate and PMMA), PET-CS (for PET) and HT-CS (for all types of polyamide, PEEK, Apec copolycarbonates and Ultem polyetherimides).

All grades of the Qualipurge CS range are suitable for the cleaning of screw/barrel and hot runner system and guarantee a much higher purging efficiency compared to their standard products, thanks to the new revolutionary formulation of the active part.

The new formula decreases cleaning time for a medium sized injection moulding machine (clamping force: 600 tons, screw diameter: 90 mm) by up to 30% and reduces the formation of scraps. Considering all factors, machine cleaning operations can be up to 90% cheaper compared to the cleaning without any purging compound.

Last but not least, Ultra System has also enriched its product line with Ultra Plast LP, a liquid purging compound that does not discharge unpleasant smokes and smells up to 400°C.

All Ultra Plast grades of purging compounds are FDA certified and apply to EU food regulation CE 10/2011 and can be used in white rooms for medical, pharmaceutical and cosmetic production. Furthermore, they guarantee a high level of sustainability, as they are 100% recyclable and allow energy and materials savings.