The global volume of turbo charged cars and trucks continues to increase year over year. As a result, the demand for more turbo air duct solutions and automotive components produced using 3D suction blow moulding technology, new materials and technologies has also increased.

To support such growth ST Soffiaggio Tecnica, DuPont and ActuaPlast thought it would be advantageous to host a “technology exchange”. The goal was to share what’s new in this industry in a way that stimulates new ideas that foster additional opportunities. The industry reaction to the concept was so high that a second day was added. The event was held on March 15 and 16, 2016. Each day hosted 50 industry experts.

The morning session for each day was held at the Hilton Embassy Suites in Livonia, Michigan to introduce the technology, the experts and the products. Each of the three companies also presented their core businesses and products as preparation for the PM session.

A shuttle

bus then transported the guests to the headquarters of ActuaPlast North America,

where the afternoon was a “hands on session” broken down into five different

stations. Participants enjoyed the opportunity to work with ST blow moulding

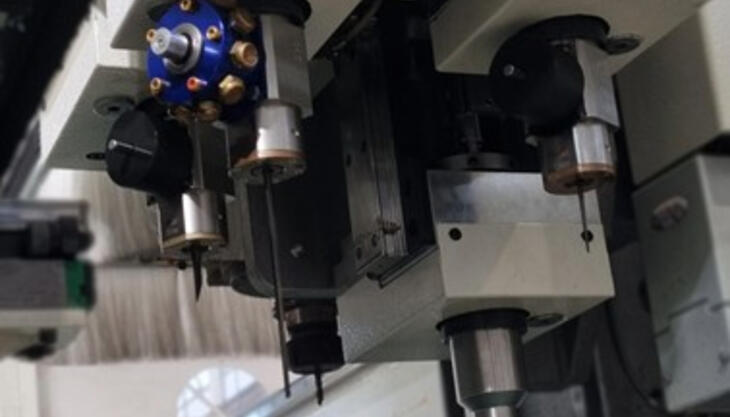

machines (model ASPI 150.2) at ActuaPlast running two DuPont thermoplastic

materials (Hytrel and Zytel) manufacturing finished parts. A welding station

was operational showing how to IR weld parts being manufactured from the

thermoplastic elastomer Hytrel 8730 (TPC-ET co-polyester) by DuPont.

A shuttle

bus then transported the guests to the headquarters of ActuaPlast North America,

where the afternoon was a “hands on session” broken down into five different

stations. Participants enjoyed the opportunity to work with ST blow moulding

machines (model ASPI 150.2) at ActuaPlast running two DuPont thermoplastic

materials (Hytrel and Zytel) manufacturing finished parts. A welding station

was operational showing how to IR weld parts being manufactured from the

thermoplastic elastomer Hytrel 8730 (TPC-ET co-polyester) by DuPont.