This is precisely what Dega set out to offer when developing its new FJH drying system, which, according to the manufacturer (in 2018 celebrating 40 years in business), should be regarded not as the best product of its kind, but rather as a superior product. Following the application of new concepts and new technological solutions, perfection is here taken to equate with level of efficiency, and this has been found to be 99%.

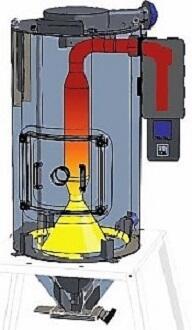

FJH is a drying system that can be readily converted into a dehumidification system, and both processes are managed completely autonomously by software which acts on air flows (the heart of the entire process), regulating and optimising them. Furthermore, the presence of an internal boiler means that it is no longer necessary to wait for the system to heat up after being started up, and this, in turn, translates into energy savings.

Every component has been designed to work and, above all, interact optimally with the others, thereby eliminating unnecessary parts of the system, boosting the efficiency of the entire process, and cutting waste and maintenance. This has made it possible to reduce the system’s installed power and achieve a significant reduction in kW consumption.