On Thursday, April 11, Bausano opened the doors of its Rivarolo Canavese (Turin, Italy) factory to welcome around 60 customers and partners for an open day devoted to the production of plastic granulate, PVC in particular. The day-long event, organised by this renowned extrusion line manufacturer kicked off with a brief presentation of the company by its vice-president Clemente Bausano, who retraced the main stages in its history, before focusing on the main technical innovations introduced more recently.

“You all know very well that energy is among the costs that impact most on a company’s turnover”, Bausano began. “In fact, energy costs make up the third largest item of cost in the budgets of plastic companies, and it is crucial to contain them in order to retain high competitiveness on the market, as long as this is not at the expense of the functionality and efficiency of production processes, of course”.

Extruders

are the main energy-intensive machines within companies that make plastic

products. The new MD Next Mover extruder series has thus been designed by the

Bausano technical team to offer a series of innovations, which clearly set it

apart from other technologies for the production of plastic granulate, profiles

and pipes. The aim, in introducing the new Next Mover range, is to allow plant

energy analysis through a control system (Digital Extruder Control) that

measures all the energy flows and generates graphs and tables from which it is

possible to verify the exact granulate consumption during the production

process. Starting from these data, consumption levels can be compared with

reference values and this, in turn, makes it possible to define specific “efficiency”

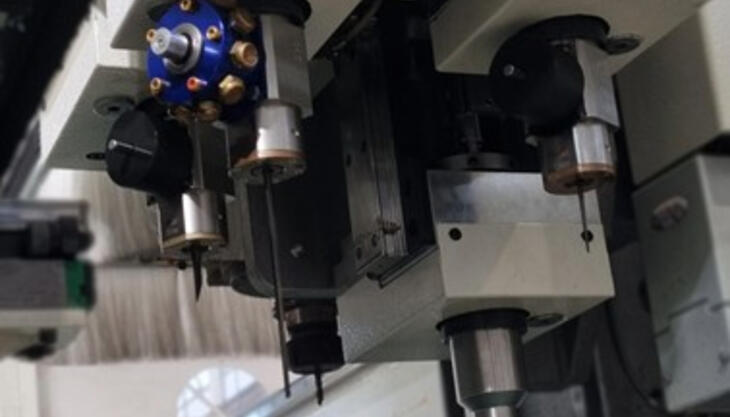

measures. The Next Mover twin-screw extruders are characterised by energy

savings of around 30-35%, obtained by installing new IE4 drives, equipping the

plants with Bausano’s patented gear box (Multidrive System), and above all incorporating

the new induction heating system for the barrel.

In the

induction heating process, the metal of the barrel is exposed to an alternating

electromagnetic field generated by a current-carrying coil. This contact-free

process generates parasitic currents in the material, which in turn produce

heat. The entire Bausano Smart Energy package also includes a special ventilation

system that allows the hot parts of the machine to be cooled down as efficiently

as possible.

After the “theoretical presentation”, the Open Day continued with a tour of the facilities and a convivial lunch in a historic restaurant in Rivarolo. Last, but certainly not least, in the afternoon the participants had an opportunity to see for themselves the innovations previewed during the morning.

Indeed, in the company’s testing and R&D area, they were able to watch tests on a line, based on an MD 158/21 Next Mover extruder, that incorporates the new induction heating system, and by monitoring the line’s energy consumption levels they were able to get a very real idea of the advantages offered. The material being processed was rigid PVC in powder form. This particular line will shortly be delivered to a processor in the Dominican Republic.