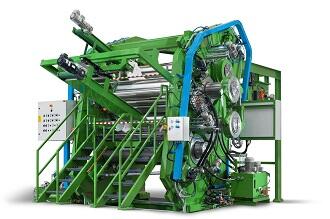

One of the major tire manufacturer in the world commissioned from Rodolfo Comerio a new calendering line for its plant in India. Featuring a 1,900 mm wide calender, this “supercombined” calendering line will be able to produce rubberized textile cords and inner liners, with the possibility to prearrange it for the future production of rubberized steel cord.

The new generation calenders, provided with the patented RC SF-FreeSystem friction-free roll shifting system, allow high-performing tires to be manufactured, thanks to: the improvement of the cords end-count per inch (EPI or EPD) and of the rubber penetration into the textile or steel cord; the reduction of the thickness and improvement of the thickness accuracy; the improvement of the tires rolling performance, resistance and stability. All this results in a reduction of scraps and raw materials used, and in consequent savings in terms of production costs and vehicle fuel consumption.

The new technologies and systems adopted for the pre- and post-calendering sections made it possible to significantly increase the line’s productivity. Moreover, the manual interventions by the operators have been reduced thanks to a highly automated production process, and consist of simply supervising the operations performed by the machines.

The supercombined calendering line will be able to exceed a daily productivity of 370 tons, and will be used to produce material for all types of tires, from giant ones for agriculture to tires for cars, motorcycles and 3-wheel vehicles. The line will be manufactured at the facilities located in Solbiate Olona, near Varese, where Rodolfo Comerio builds all its new-generation calendering lines, equipped with the “RC TURN-KEYinstallation” pack ensuring increasingly faster installation, commissioning and service times.