Termoplast, a leading Italian company in the production of polyolefin technical films for flexible packaging, has been dedicated for many years to the study of new solutions able to meet the most critical market needs in compliance with current regulations in terms of sustainability.

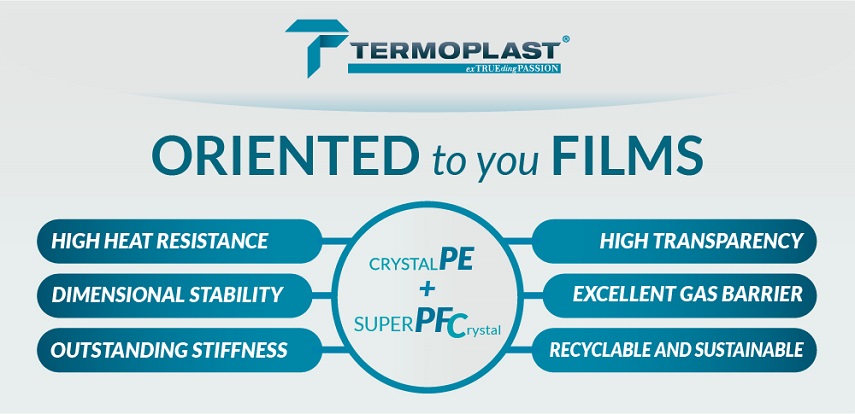

Termoplast has developed two new product families dedicated to the creation of monomaterial structures suitable for recycling, thanks to the coextrusion-orientation technology called CRYSTAL. These two product families called CRYSTAL PE and SUPER PFC have shown outstanding characteristics worthy of the best known multi-material non-recyclable laminated structures on the market.

Termoplast has developed two new product families dedicated to the creation of monomaterial structures suitable for recycling, thanks to the coextrusion-orientation technology called CRYSTAL. These two product families called CRYSTAL PE and SUPER PFC have shown outstanding characteristics worthy of the best known multi-material non-recyclable laminated structures on the market.

The non-barrier CRYSTAL PE films, proposed as supports for flexo/rotogravure printing and lamination, are available in thicknesses up to 20my and with mechanical characteristics adaptable to any type of application. They are also available in low-sealing temperature version, with different degrees of slipperiness, from 20my up to 50my.

Thanks to the high mechanical and thermal resistance properties, they are the optimal solution for applications which, at significantly reduced thicknesses, allow to create packaging with performances comparable to laminates with PET and/or PP, with excellent processability on all packaging flowpack machines, but above all recyclable.

On the other hand, where high gas barriers are required, SUPER PFCs take over and thanks again to the CRYSTAL technology applied to coextruded structures with EVOH, offer barrier characteristics superior to conventional films, excellent optics and mechanics not comparable with any PE currently used. Available in AntiFog, Peelable and low sealing temperature versions, once laminated with CRYSTAL PE, they allow you to replace a very high percentage of laminates in any application, thus obtaining RECYCLABLE structures with significantly reduced thicknesses.

Tests, carried out on trays, stand-up-pouches, doypacks with valve, pillow bags, lap-seal bags, gave extremely positive results in terms of processability and productivity on all packaging lines.

Termoplast is also active in the study and development of Biobased films and films with high PIR and PCR content in order to satisfy the always growing demand to place highly sustainable products on the market and reduce CO2 emissions into the atmosphere as much as possible.

For further information, you can visit the company's website www.termoplast.it or call 0571 65051.