Piovan at Fakuma with debutants and confirmations

PiovanGroup takes part in Fakuma 2024 with its brands Piovan, Piovan Fdm, Pelletron e Thermal Care, exhibiting an overview of the latest technological innovations resulting from intensive R&D activities in the field of automation systems for plastics processing. In particular, a complete range of dedusting, feeding, conveying, storage, dehumidification, dosing, temperature control and cooling systems is on display.

Several novelties from the group make their debut in Friedrichshafen. HandlinkEvo is the manual coupling station that allows the operator to correctly match material sources to receivers, reducing errors thanks to a system of flashing coloured LEDs. It can be equipped with Easy3+, to manage centralised feeding systems, which verifies the correct locking or matching of source and destination. In case of problems, such as an open circuit or material mismatch, it stops the feeding cycles and alerts the operator. The new compact dust collector C20 deduster is designed to remove dust and angel hair that can cause imperfections. The design facilitates retrofitting, making it ideal for injection moulding and extrusion processes.

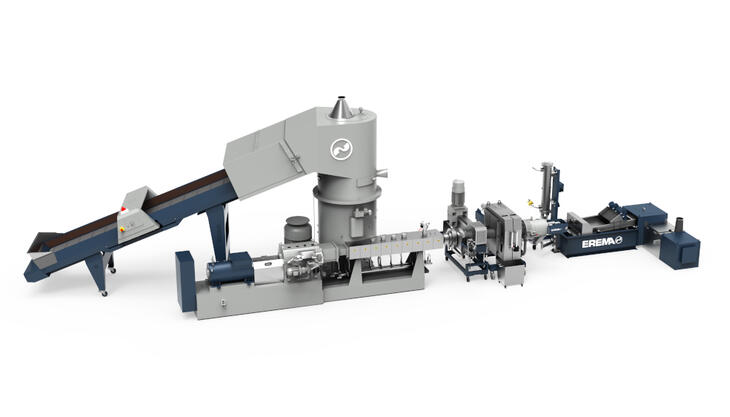

GDS-5E is the new gravimetric dosing system developed by Piovan Fdm, suitable for granules, additives and powders. It supports extruder operations in overfeed and underfeed modes, ensuring full control of the extrusion line. The new gravimetric dosing unit Easyfeed+ is available in 4 sizes with throughput up to 200, 400, 600, and 800 kg/h and with variable configurations from 2 to 5 ingredients specifically designed for hungry mouth extrusion and injection molding processes, which require high dosing accuracy and homogeneous dispersion of additives. Quantum+ is the gravimetric dosing unit that guarantees high dosing precision and accuracy, encompassing all the technical advantages of Quantum and MDW in a single equipment, in a perfect combination that makes it suitable for processing all plastics.

Different Piovan branded products make up the group's exhibition programme. The Modula multiple hopper drying system for injection processes automatically adjusts and controls all operating parameters of each individual hopper, using only the total amount of energy strictly necessary; the DPA compressed air dryer is presented in a special medical edition in combination with Moisture Minder, the solution for the in-line measurement of the moisture in the plastic granules with full traceability and monitoring of the production process; the Easylink+ automatic coupling station handles up to 60 inlets/outlets with pipe sizes from 40 to 76 mm with a minimum footprint; the Pureflo vacuum receiver is equipped with Ryng for real-time production monitoring and the usage of the raw material; through a 3D demo, the innovative Easypure odour removal system is illustrated equipped with Odor Minder, the electronic nose designed to improve the deodorisation process in terms of effectiveness and efficiency.

In the field of cooling and temperature control is proposed the Easytherm complete range of temperature controllers - water, pressurised and oil - under the Thermal Care brand characterised by heat exchange efficiency and process reliability. At the fair are displayed the Easytherm EW open-system temperature controllers for temperatures up to 90 °C; the Easytherm ETP100 pressurised temperature control units for a wide range of flow rates, pressures and water temperatures; the Easytherm Flow temperature controller with high flow and head up to 140 °C, 300 l/min or 130 m head, with reduced process start-up times. Also on display the Slim 1111 air-cooled chiller with a compact design, capable of handling ambient air temperatures up to +40 °C, applicable to all industries, providing maximum flexibility and energy-efficient operation.

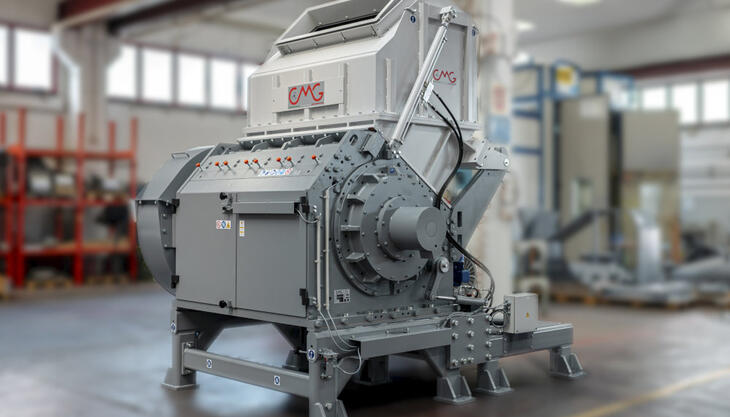

Pelletron, the group's company specialising in the production of plastics conveying and dedusting solutions, in addition to the C20 deduster, presents the DeDuster XP15, a series specifically designed for the plastics production and compounding industry, available for unloading capacities from 500-1500 kg/h of all types of granular products that need to be cleaned prior to packaging, shipping or processing. Thanks to its low height, the DeDuster XP series can be installed on bagging machines or moved under or between storage silos.

Finally, at the fair it is possible to try out Winfactory 4.0, the software for the control and management of production process developed by Piovan for the supervision of the digital factory, which enables the tracking of every single batch of raw materials and finished products.