Covestro provides Signify with polycarbonate for 3D-printed luminaires

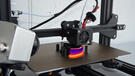

The world leader in lighting Signify is expanding its printing capabilities in the Netherlands and plans to establish new facilities in the USA, India and Indonesia. To this scope, Covestro is providing the company with polycarbonate for its capabilities for 3D printing. Signify has perfected 3D printing as a highly and more sustainable form of manufacturing luminaires.

Signify chose for polycarbonate from Covestro, as it fulfills customer requirements like high impact and heat resistance, design freedom, transparency and flame-retardance, which allows luminaires to be quickly designed and tailored to customers´ exact needs. Not least, it is 100% recyclable, supporting the concept of a circular economy.

“We are the first lighting manufacturer to produce 3D-printed luminaires on an industrial scale. This reinforces our position at the forefront of lighting and sustainable innovation,” said Coen Liedenbaum, Venture Manager 3D Printing at Signify. “Customers are able to bring their ideas to life in a matter of days rather than months, and printing uses less energy.” The company announced that it was providing printed luminaires to multiple major retailers.

Successful upscaling

“Covestro offers a comprehensive range of polymeric materials for all common 3D printing methods, including polycarbonate raw materials for this promising application,” explained Patrick Rosso, Global Head of Additive Manufacturing. “By partnering with companies like Signify, we are pushing existing scale boundaries and supporting various industries along the value chain on their way to digital mass production.”

Covestro is currently researching materials to enable an extended range of industrial applications. To this end, the company is upgrading laboratories for 3D printing at its Leverkusen, Pittsburgh and Shanghai sites, where it develops and tests material solutions for serial additive manufacturing in collaboration with different customers.

Signify´s investment further illustrates the company´s commitment to better serving its customers while reducing their, and its own, carbon footprint. The company´s 3D-printed luminaires are designed for a circular economy as nearly every component may be reused or recycled.

Strategic program to promote circular economy

Covestro regards the circular economy as a key topic and has launched a long-term strategy programme for this purpose. “Our company wants to shape the transition from a disposable economy to a circular economy with as many partners as possible,” said Rainer Rettig, Head of the Circular Economy program at Covestro. “To this end, we already provide our customers with tailor-made products today. This project is a wonderful example for this.”

“Our finished luminaires have a 47% lower carbon footprint than traditionally built metal luminaires,” added Coen Liedenbaum. “They also weigh less, which allows us to reduce the carbon footprint in shipping by 35 percent. And by keeping production locally we reduce the footprint even further.” Signify plans to integrate energy-efficient LED lights into its luminaires at all existing and new production sites.